Nestlé seeks to patent aseptic closure for 'non-destructive' spoilage detection

The international patent application, filed by Nestlé’s research arm Nestec in March 2014, details a closure system for containers of aseptically-filled fluids, such as liquid infant formula.

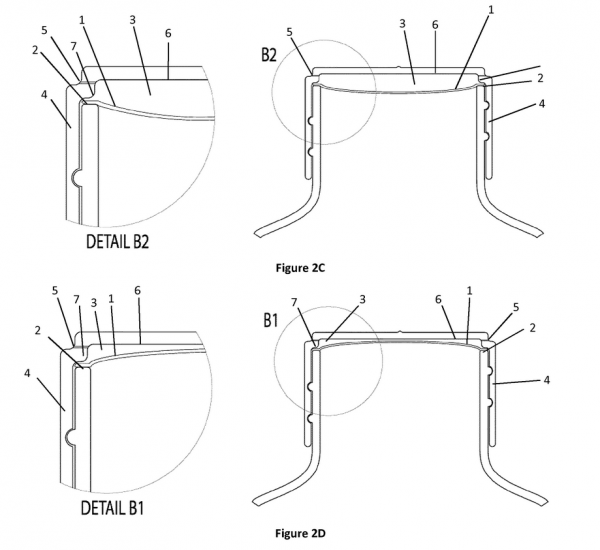

The patent-pending invention combines a cap with a “head space extending over the top of the container opening” and a “foil seal on said top of the container opening.”

Vevey, Switzerland-based Nestec claims in its patent that the system is "particularly advantageous in that allows for a clear detection of two different states of the content of the container: the aseptic and the spoiled state."

“In the aseptic state, the foil is either flat (pressure is the same inside and outside the container) or the foil is deflected towards the interior of the container (pressure lower inside the container than outside)," said the patent application.

“In the spoiled state, the foil is deflected above the top of the container opening towards the exterior of the container and thus extends into the head space.”

The detailed process involves first aseptically filling a container before sealing its opening with a removable flexible foil.

The cap is then added, creating space between the foil and the cap to allow the foil to "deflect" as a result of increased pressure in the container.

The inventors, Nestec R&D duo Niels Stoffers and Lutz Ellmann, tested their brainchild on bottles of liquid infant formula.

They applied the closure system, consisting of a screw cap and flexible foil, to two batches of liquid infant formula.

After one month of storage at room temperature, the deflection of the foil in head space was measured using an inductive sensor - one that detects metal objects without touching them.

These were compared with two sets of controls bottles - one set in the aseptic state and one in the spoiled state. All bottles were tested without removing the screw cap.

"Results of the detection were checked by visual examination of the bottles," said the patent application. "This confirmed the spoilage detection method was successful in distinguishing the bottles in the spoiled state from he ones in aseptic state."