Milk processor extends machine lifespan thanks to oil-impregnated bearings

The Molded-Oil bearings will save the company approximately £10k ($12k), because the bearings do not need to be refilled as oil is released internally when needed, lubricating the bearing for extended periods of time.

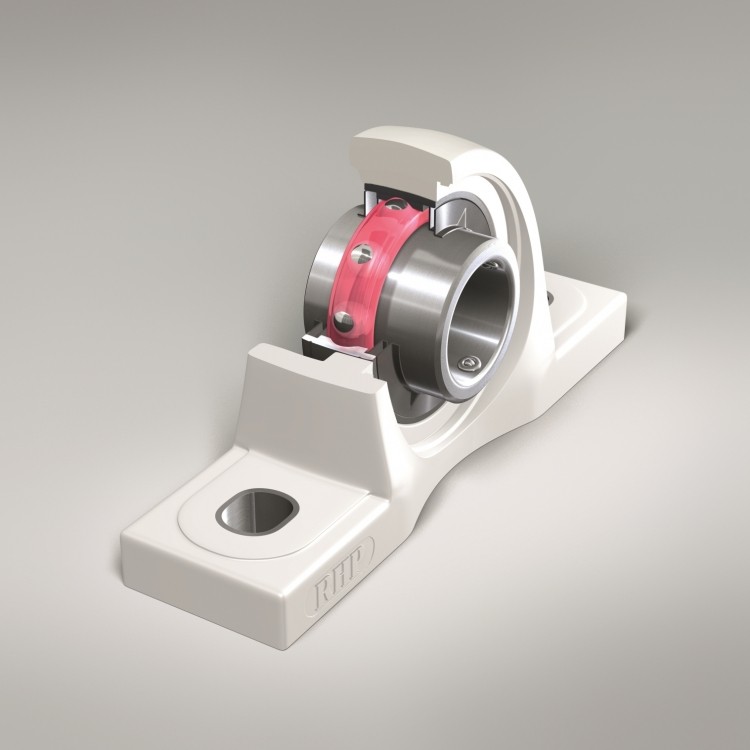

PBT thermoplastic resin

This was combined with Silver-Lube corrosion-resistant housings, made of PBT (polybutylene terephthalate) thermoplastic resin, which are paint-free, avoiding any chipping or flaking. Both the housings and Molded-Oil inserts comes from NSK's Life-Lube series.

The range is designed for applications where contact with process fluids is unavoidable, and is available in 20-40mm bore sizes and in pillow block, two- and four-bolt flanges, and take-up unit housings.

The milk processing plant, which NSK refused to name, was experiencing regular failures of multiple bearings on its conveyor, and because they were in an inaccessible area they could not be re-lubricated.

The client had to change the bearings every 10 weeks, which led to downtime of three hours each time.

During trials, the milk processing plant reported the life of the bearings on the conveyor were extended from 10 weeks to more than a year, and it didn’t need to replace the shaft when each bearing failed.

Lost production time

This cost, along with the labor costs associated with deploying two maintenance fitters, and cost of lost production time, came to annual savings of more than £10k.

Silver-Lube has nitrile rubber seals, it is NSF (National Sanitation Foundation) –approved; available in four geometries and suitable for temperatures from -20°C to +90°C.

NSK develops and manufactures precision components and mechatronic products, as well as systems and components for the automotive industry, including wheel bearing units and electric power-steering systems.

It opened its first European subsidiary, in Düsseldorf, Germany, in 1963 and a European production facility in Peterlee, UK, in 1976. It has logistics centers in the Netherlands, Germany and the UK and technology centers in Germany, England and Poland.