Manufacturers 'ignoring' the energy value of dairy production residues: Clearfleau

Speaking with DairyReporter.com, Richard Gueterbock, founder and marketing director, Clearfleau, said dairy fats and by-products “are particularly suited to anaerobic digestion."

Despite this, British dairy interest in anaerobic digestion - the process of breaking down biodegradable material in the absence of oxygen to generate biogas – is only now building, he said.

“Many companies have to pay for the cost of disposal or treatment of these residues, and they’re ignoring the energy value those residues could have,” said Gueterbock.

“Anaerobic digestion is not a new technology, it’s been around for a while.”

“In the UK, we have been relatively slow on the uptake – as we have been with many renewable energy technologies.”

“We would have hoped to have done more dairy plants,” he said, “but milk prices are under pressure, which has caused dairy companies to concentrate on their core business rather than production residues.”

Bio-methane

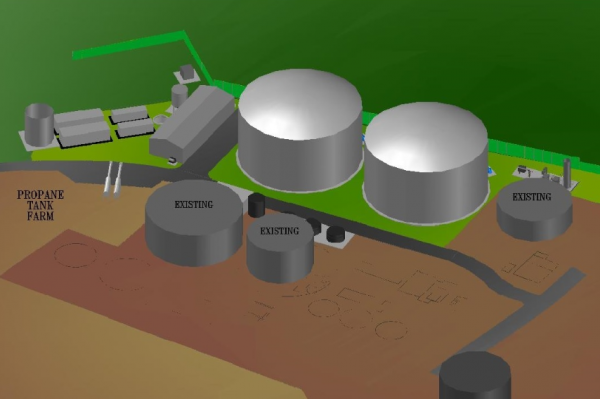

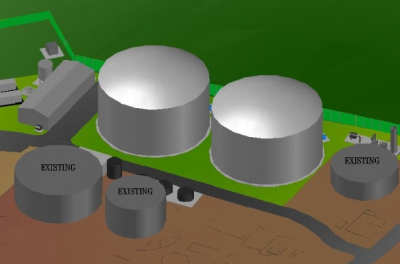

Clearfleau recently completed the first phase of construction of an anaerobic digestion plant at First Milk’s Lake District Creamery in Cumbria.

Once fully operational, the plant will convert whey permeate – a by-product of cheese production – into approximately 1,000m3 of bio-methane per day.

The bio-methane will be cleaned and fed into the gas grid network - "a first" for the dairy industry, according to Gueterbock.

First Milk will use some for steam generation at its Lake District Creamery.

Gueterbock declined to discuss the size of First Milk's investment in anaerobic digestion technology, but said a medium sized dairy would likely face a bill of between £2m and £2.5m.

For a smaller dairy, he said, the cost could be less than £1m.

Gueterbock acknowledged that given global pricing pressures the generation of biogas may not be a top priority for many dairy processors.

“That’s why we developed a process where we help finance the project," he said. "For any company in the dairy industry that wants to look at this technology it is quite possible to arrange the finance.”

Others, however, have not been put off, he said.

“We’re talking to a number of dairy companies and we’re at different stages. We hope to be building another in the dairy industry in the next year.”

“We’re even talking to one or two dairy companies outside the UK," Gueterbock added.