ProcessExpo 2017

Powder Solutions Inc. assures product safety with hands-free automated metal detector

A traditional and commonly-used magnetic separator for powder processing is dependent on an operator who must come into contact with the powder periodically to wipe off the metal debris collected during the magnetic separating process.

“You’ve got a couple of potential issues there,” Powder-Solutions CEO, Marv Deam, told DairyReporter at ProcessExpo in Chicago last week.

“You’ve got powder spillage in your dairy plant; you’re opening up the process to the atmosphere so contaminants can go inside and these are extremely strong magnets so you have a good potential of operator injury.”

Another issue with the operator-dependent method is the downtime it takes for an operator to come in and wipe down the machine.

“You could easily have 30 minutes of production downtime,” Deam said.

Self-sufficient solution

The MAG-RAM magnetic separator has self-cleaning capabilities that wipe off magnetic contaminants and send them to a separate chamber, minimizing human involvement and any spillage of powder that may occur from the separation process, the company said.

The MAG-RAM by MAGNATTACK received the Innovation Showcase award for the dairy category at Process Expo 2017.

Available magnetic separators are able to separate both small, ferrous materials and large metal contaminants from the powder stream, according to PPS.

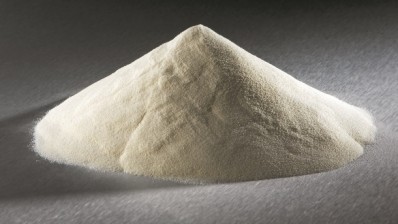

In an era of increased food safety recalls, the company believes Magnattack can provide food safety assurance to its customers and the final product for consumers such as whey and lactose.

“We’re selling to a lot of the major whey producers and they’re so concerned with Food Safety Manufacturing Act (FSMA),” Deam said.

Dairy products topped the list of the most FDA food recalls in 2015.

“Nobody wants to have a recall because now recalls are so public,” Deam added.

“Food safety should not be considered a competitive advantage by any one company. They should all focus on helping each other be as good as they can be.”

The machine also meets HACCP standards and is USDA dairy compliant, adding an extra level of food safety assurance.