PurePulse makes raw milk safe, says CoolWave

However, it can’t be used in the Netherlands because of laws that state store-bought milk must be pasteurized.

Electric pulses inactivate bacteria

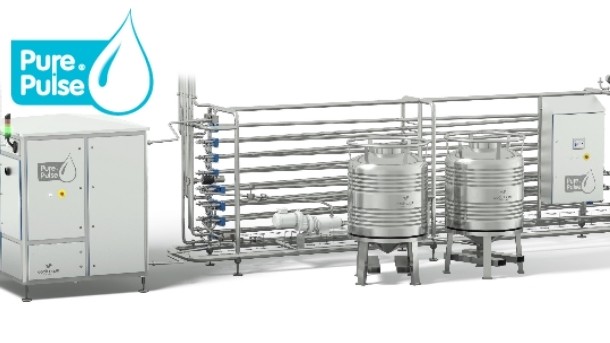

PurePulse is a preservation method in which a series of short electric pulses are generated, and it is these pulses that inactivate bacteria in the food.

This accomplishes a shelf life comparable to heat-pasteurized products, but CoolWave says heat-pasteurization changes the nutritional value and taste of milk.

However, CoolWave says, the electric pulses from PurePulse don’t heat the milk, and therefore proteins and other healthy components of raw milk that would be destroyed by heat pasteurizing are preserved.

Laws prevent introduction

CoolWave says that laws in the Netherlands mean that only heat-pasteurized or sterilized milk can be sold freely in the supermarket.

A company spokesperson told DairyReporter that the technology is currently not being used by the dairy industry, in spite of it being able to, simply because of the regulations.

“We are trying to move the Dutch Food Legislation Authorities to make it legal for dairy producers to use this technology to make safe and better quality fresh (raw) milk, but we have not yet succeeded in this.”

The company says that the ‘old laws’ do not take into account the possibilities of modern technology, like PurePulse.

It points to scientific research over the past ten years that CoolWave says has delivered sufficient evidence for its effective use. The technology has already been developed to an industrial scale.

Potential for yogurt and cheese

In cooperation with dairy companies and dairy farmers, CoolWave is also researching the possibilities for processed dairy, including yogurt and cheese.

The PurePulse technology is currently being utilized in juice processing, however, it has only recently been applied to the dairy industry.