Nano-coatings cut milk fouling in gasketed plate heat exchanger - research

The study from the University of Bremen in conjunction with GEA Ecoflex found that that heat exchanger surfaces treated with the coating had low surface energy – and therefore wettability. This led to a greater resistance to the build up of oils and waters – so-called hydrophobic and oleophobic effects - in the equipment, said the paper published in the journal Food and Bioproducts Processing.

Dairy production problems

The study was launched in a bid to tackle typical dairy processing problems can arise as a result of the wall wettability from two sides – the production time and cleaning procedure. The deposits that build up means the plates need “regular and intensive cleaning” in order to meet hygiene and quality standards, said A Bani Kananeh et al. Deposits have the potential to damage product efficiencies through the reduction in heat transfer from equipment and by increasing the pressure drop. The study estimates that fouling in the dairy industry and the resulting cleaning of the equipment can account for up to 80 per cent of production costs.

Gasketed heat exchangers with stainless steel plates are commonly used in the dairy sector because of a number of perceived advantages over shell and tube heat exchangers.

Nano-coatings

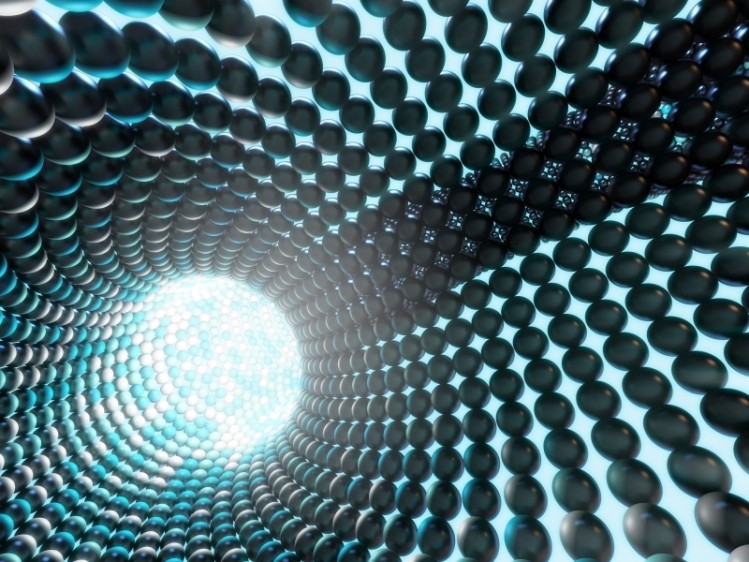

The researchers said the application of nano-coatings reduces the build up of deposits by decreasing the surface energy of the metal and therefore boosts the operational efficiency of the system.

The research investigated both the extent of milk adhesion and stability of the coatings on rectangular plates and small cylindrical ducts. They found that certain polyurethane-coated plates and tubes formed thinner deposit layers compared to standard uncoated stainless steel counterparts.

Following this, a pilot plant that included a milk sterilizer was established for the thermal treatment of the whey protein solution. Both a range of nano-coated and electro-polished plates were fitted in the heating section of the pasteurizer.

The researchers noted there were “significant differences” between the coated and uncoated plates – with the coated surfaces showing a reduced deposit build-up in comparison with the uncoated stainless steel plates. Polyurethane-coated plates had the thinnest deposit layer.

But the study also found that the performance of the electro-polished plates in reducing deposit build up was not only superior to non-coated plates but “were almost comparable to the coated plates”. The cleaning in place (CIP) time of the coated plates was reduced by 70 per cent compared to standard stainless steel plates.

The coatings must be further developed to be able to withstand the thermal and mechanical stresses in the industrial process, said the German researchers.

Reduction of Milk Fouling Inside Gasketed Plate Heat Exchanger Using Nano-Coatings by A. Bani Kananeh, E. Scharnbeck, U.D. K¨uck, N. R¨abiger published in the Food and Bioproducts Processing. DOI: doi:10.1016/j.fbp.2010.09.010