X-ray technology used in mining industry proves successful for controlling sodium levels in cheese, study finds

The method will allow cheesemakers to adjust sodium levels during the cheesemaking process using X-ray fluorescence spectroscopy (XRF).

The standard method for measuring sodium in cheese, the Volhard method, indirectly measures sodium in cheese by analysis of chloride, assuming the all chloride present in the cheese sample came from NaCl (sodium chloride). According to the study, this overestimates the amount of sodium present in cheese, when sodium replacers are used.

Direct measurement of sodium content in foods is commonly done using atomic absorption spectroscopy, however this technique is costly, laborious, and requires complex sample preparation that often takes days to obtain results.

“The bottom line was there was a significant amount of sodium variability in cheesemaking that really uncovered the need to address this,” Bill Graves, vice president for product research at Dairy Management Inc., told DairyReporter.

"The key thing is you want to give cheesemakers a tool to measure directly and rapidly in real time so they can makes changes during the cheesemaking process."

Borrowing from the mineral industry

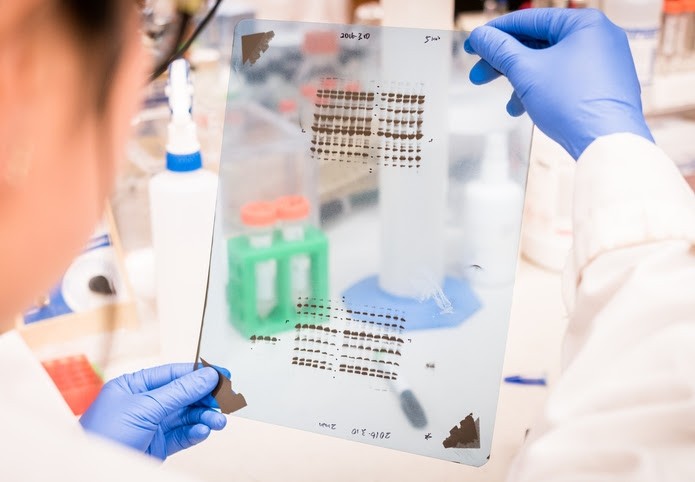

XRF, a mineral analysis technique used in the mining industry, proved to be a rapid and reliable method for the routine determination of sodium in natural cheeses. In addition to the speed of relaying results to scientists, X-ray fluorescence is also precise, nondestructive, and a potential alternative method for direct sodium determination in foods outside of cheese, the study stated. The XRF technology also has the ability to measure and control the amount of other minerals such as calcium, Graves said.

In order to accurately test the efficacy and accuracy of XRF for detecting sodium levels, a wide range of sodium concentrations were prepared using natural cheeses including, cheddar, Gouda, mozzarella, and nonfat cheese. The cheese was finely shredded and different amounts of sodium chloride were stirred into the cheese and stored for one week at 4°C to allow for sodium equilibration.

While the XRF method was successful in accurately measuring and controlling Na levels in natural cheeses, the study found that XRF could not be easily used on more processed cheese such as American cheese, which contains more complex mineral makeups and likely due to the use of Na-based emulsifying salts.

According to Graves, processors making natural cheese varieties will be able to benefit from the XRF method of analysis by gaining rapid results (15-20 minutes) of sodium levels and make adjustments as needed during the cheesemaking process compared to current sodium analysis techniques.

"The technology is ready to have cheesemakers adopt it nationwide," Graves said.

Source:

Journal of Dairy Science

DOI: http://dx.doi.org/10.3168/jds.2014-9055

'Evaluation of X-ray fluorescence spectroscopy as a method for the rapid and direct determination of sodium in cheese'

Authors: J.A. Stankey, C. Akbulut, J.E. Romero, S. Govindasamy-Lucey