Sealed Air cuts down labor and improves food safety with BL75 bag loader and Grip & Tear packaging

Since its introduction to the North American market 12 to 15 months ago, three BL75 units are currently in operation and another three to six will be coming online by the end of the year, John Kelly, North American marketing director for Sealed Air Dairy Packaging, said.

According to Kelly, much of the positive feedback Sealed Air has received around the BL75 is based on its ability to cut down on labor costs and its operational flexibility.

“It’s very flexible from machine change tooling to swapping various product sizes,” Kelly told DairyReporter.

“I think what’s generated a lot of excitement is that the fact that this ties in very nicely with our current infrastructure,” he said.

“You think about our rotary chamber machines typically in place already, so it’s a really plug-and-play solution for a number of customers.”

It is also a simple bolt-on solution to setups not necessarily using Sealed Air equipment, Kelly added.

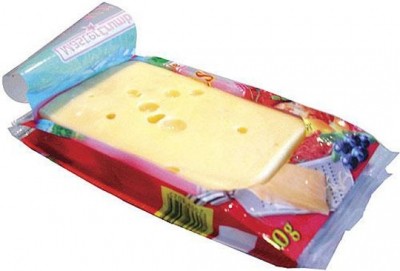

Grip & Tear dairy packaging

“A lot of the research we’ve done, we found that consumers in a lot of cases are dissatisfied with the ease of opening,” Kelly said.

Sealed Air’s Grip & Tear packaging addresses end users’ needs for easy-to-open cheese packaging. Grp & Tear packaging was originally developed and commercialized for the poultry and cured meats categories, and has more recently been used in the dairy industry.

“The primary benefit is food safety, whether it’s process customers or end users that we talk to,” Kelly said.

“This package can eliminate the need to use knives or other sharp implements to open packages.”

The two main product areas that Sealed Air has seen success for Grip & Tear are for larger pieces of cheese such as five to 10 lb cheese loaves behind deli counters or for consumer-facing cheese blocks and wedges ranging from six ounces to two lbs, Kelly said.