Donaldson LifeTec filter line innovates dairy microfiltration space for the first time in decades

The company is valued at $2.5bn and invests about 2% of its operating net profit back into research and development.

“There really hasn’t been any innovation in this space for I would say thirty to forty years,” Jessica Exley, director of process filtration at Donaldson, told DairyReporter.

“There’s a significant need by our customers that we feel like we’ve really addressed.”

According to Exley, those needs called for longer cartridge filter life and a high level of media in the cartridge housing to filter out all contaminants.

Launched globally, the LifeTec filtration line was recently introduced to the North American food and beverage industry.

The filters are available in a range of configurations and can be custom produced from 10 to 40 inches in length and customers can choose from three filtration media types: polyethersulfone (PES), polypropylene (PP), and polytetrafluorethylene (PTFE).

The importance of cartridge strength

Donaldson added 20% more media to its filters, which translates into higher microfiltration capabilities compared to standard filters and raises the overall integrity of the product in regards to strength and reusability.

“I think people are recognizing the fact that what’s gone unnoticed is the importance of having strength,” Exley said.

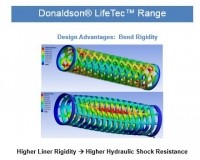

A major feature of the LifeTec filtration line is its durability and strength through its diamond pattern design, which prevents hairline fractures and cracks, even when the filter is over twisted. According to Exley, the majority of filters on the market use a rectangular internal cage design, which isn’t as twist resistant and is not as structurally sound.

Steam used to sterilize both the equipment and the sterile-grade filters also presents another opportunity for the cartridges to become “soft” making them even more susceptible to damage and fractures.

“That could lead to bacteria or other contaminants getting downstream, which in a dairy plant is extremely dangerous and a problem for food safety,” she said.

In addition to the higher durability, it has other inherent benefits such as a longer service life, translating into a lower cost of ownership and less downtime because end users are not having to stop the process to replace cartridges.

Meeting and elevating the sterile standard of dairy

“The food and beverage industry is so regulated and the requirements on the materials, the sanitary design, the bacteria design on filter housing and equipment is so unique,” Exley said.

“And dairy is even a step above a lot of food processing with 3-A Standards and sanitary design.”

LifeTec filters are made from FDA-approved materials suitable for direct and indirect food contact, the company said in press release.

Taking it one step further, the filters meet the 3-A Sanitary Standards – a set of more stringent and uniform standards for dairy processing equipment created in the 1920s. The objective of these standards is to protect food from contamination and ensure that all product contact surfaces can be mechanically or manually cleaned, according to Donaldson.

By adding 20% more filtration media, Donaldson said it has also solved the challenge of improving dirt-holding capacity.

“This filtration is used for both to protect product integrity, to make sure that in the final product that the flavor is strong, that there’s no bacteria, the shelf life is there, and then also the process is repeatable,” Exley said.