Netzsch solves 25-year-old dairy problem with sticky pump

The Nemo pump provided by Netzsch features a flexible rod design that eliminates the need for lubrication and protection against mechanical damage or corrosion. Since its installation, the pump has significantly reduced pump downtime, resulting in time, labor, and money savings.

Sticky pumping issue stumps dairy products company

The country’s largest producer of sweetened condensed milk had endured decades of issues associated with pumping the mixture of milk and sugar – the primary components of sweetened condensed milk – out of two flash coolers near the end of the manufacturing process.

The application includes pumping the mixture of milk and sugar ranging from 1500 to 5000 centipoise (CP). Pumping is conducted at about 40 gallons per minute (GPM), pulling from two vessels under vacuum (24-inches and 28-inches).

The pump had to maintain pressures of 150 pounds per square inch (PSI) with operational temperatures of 70-120°F. Cleaning in place (CIP) is conducted at 50 GPM, pulling from the vessels 2 to 26-inches with a vacuum of 20 PSI, using a caustic of 6% and nitric acid of 3%.

One of the company owners recalled the long and difficult history of trying to find suitable pumps for this application.

“When we commissioned the evaporator 25 years ago, we had rotary lobe pumps in this pumping application. The metal to metal surfaces wore rapidly. We then switched to sinusoidal pumps. We tried many different elastomers, but never got good pump life. We spent a great deal on parts, and, because the pumps could not CIP, we had to hand wash the seals.”

He explains they then switched to progressive cavity pumps, and got good stator life, but had the same problem with metal-to-metal U-joint wear.

“We would lose about a half-inch of metal in four months, necessitating the replacement of the rotor, U-joint, pins, and plug-in-shaft.”

Then, moving on to a different type of progressive cavity pumps they continued to struggle with various failure modes of the booted sleeve over the U-joint. And once that failed, the joint quickly failed.

They reckon they had spent close to $500,000 dealing with this pump application – including losing entire batches of sweetened condensed milk.

Flexible shaft pump results in application success

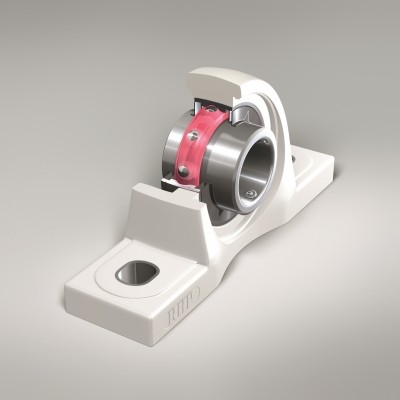

In 2014, the company contacted Netzsch to find an answer to this long-running production problem. Netzsch engineers recommend using the Nemo progressing cavity pump with a flexible shaft.

The patented flexible rod design is free from crevices and dead spaces, and is often used to produce foodstuffs, and in a variety of other pharmaceutical, cosmetic, and chemical or biochemical applications.

The flexible rod design eliminates the need for double universal joints or gear joints – both of which require complicated arrangements of often small, multiple components with close tolerances, which require lubrication.

With no components moving against each other, the flexible rod eliminates the need for lubrication and protection against mechanical damage or corrosion.

Since there is no wear and lubrication required, there is no risk of product contamination. This is especially relevant in process industries, where continuous and batch production demands pumping equipment with high levels of reliability.

Made from special steel, the flexible rod is designed for 10 million load changes. It has the inherent strength to transmit the required drive, with the flexibility to withstand the eccentric motion of the rotor. The material’s other advantage is its resistance to most chemical compounds.

The pump specifications for the sweetened condensed milk application includes a pump housing, end stud, and rotor made of 316 stainless steel, with a stator composed of FDA Buna-N, NEMOLAST G66L, with a reduced wall.

The drive shaft includes the crevice-free flexible rod, and a mechanical double sanitary seal.

Problem solved

The dairy products company placed two Netzsch Nemo pumps in service in early June 2014 and then ordered a third to be used as a spare, placing it between the two operating pumps.

Since then, the two progressing cavity pumps have been running 24 hours a day, seven days a week, with no maintenance or performance issues. After several months of service, one pump was taken apart to inspect for stator or other wear – but none was found.

The company is now looking to use the progressing cavity pump in several other plant locations for existing and future operations.’

Pete Ciorrocco, regional sales manager, Netzsch Pumps North America,