2014 SPECIAL EDITION: DRIVING UP QUALITY, DRIVING DOWN COST

Academic puts smart money on smart dairy packaging

So says Dr Joe Kerry, head of the Food Packaging Group, School of Food and Nutritional Sciences, University College Cork, Ireland, in a new book that tackles the subject and name checks recent advances in the field from DSM and Dutch-based firm Shieltron.

Smart packaging encompasses two main categories, Kerry explains. Active packaging involves incorporating additives into packs (loose therein, attached to packaging, or incorporated within its materials) to maintain or extend product quality and shelf life.

Intelligent packaging senses properties of the food it encloses, and informs manufacturers, retailers and consumers of the product state – examples include RFID labels, tags, chips; time temperature indicators (TTIs) or tamper evident packs that might release a contaminant once breached.

But despite significant technological development over the past 30 years, Kerry says smart packaging application is “still in its infancy” due to an unduly restrictive attitude from regulators that stifles development and the failure of developers to engage meaningfully with retailers, and vice versa.

Food waste presses ‘hot political button’

However, Kerry predicts a significant role for smart packaging in FMCG for the following reasons: (1) product waste is now a ‘hot political button’ (2) resources are scarce, material waste is taboo (3) the cost of smart packaging is coming down (4) food and beverage prices will rise, making investment more worthwhile.

(5) The global economy will demand safer, higher quality products with longer shelf lives (6) brand protection demands authentic, safe products that smart packaging can deliver.

How does this tie-in with dairy? Well, Kerry discusses non-beverage, dairy based products – yogurt, cheese, butter, ice cream, cream, etc. – and says that their packaging formats or structures tend not to be as complicated as those used for muscle-based foods (meat, poultry and fish).

Due to the way they are manufactured and the role of microbial cultures, the academic notes that dairy products do not present the same degree of risk as muscle-based foods and also often retail as shorter shelf-life products

He explains that ‘first-level’ packaging for such dairy products involves use of single, rigid plastics such as HDPE, PP, PS, PET and PVC, while closures use the same materials and aluminium foil seals.

Laminates used within the sector are paperboard with foil (aseptic products) and without foil – fresh milk, yogurt, ice cream – or are plastic-based, primarily for cheese products.

Kerry says that smart packaging for non-beverage dairy products has mostly been adopted from the muscle-based foods sector and applied mainly to cheese and ice cream-based desserts.

Pack-Age by DSM for ripened cheese

“The most pertinent technology that was developed specifically for use with cheese is Pack-Age by DSM that was developed for ripened cheeses,” Kerry claims.

This uses a moisture-permeable foil to allow gradual moisture release and minimize free water presence in the product – combined with inhibitors to stop mold and yeast growth.

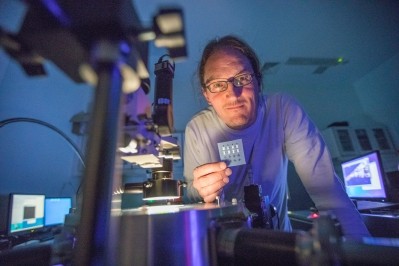

Elsewhere, Shieltronics in Holland has developed its Shieltron susceptor packaging, and Kerry says this can be used with microwaveable sundae-style products to allow fruit, syrup or chocolate toppings to be heated on top of the ice cream without causing it to melt - it is pictured here with other foodstuffs.

This patented foil system – supplied as an in-mold label, lidding seal foils or in pouches – allow microwaves to travel through packaging where the foil is not present, thereby heating the food.

Microwaves are blocked from reaching food where the foil is present, keeping the product cold.

Title: ‘New Packaging Technologies, Materials and Formats for Fast-Moving Consumer Products’

Author: Joe P. Kerry

Source: Innovations in Food Packaging, pp.549-584, DOI: http://dx.doi.org/10.1016/B978-0-12-394601-0.00023-0