Ripening times impact Listeria in Cantal type cheeses - study

Researchers ran challenge tests looking at the pathogen in cheeses under different packaging conditions and during cheese making, ripening and storage.

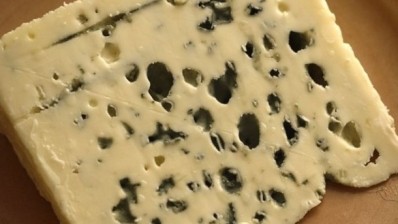

The aim was to look at L. monocytogenes growth or survival in raw milk uncooked pressed cheeses referred to as “Cantal type cheeses”.

Packaging, making, ripening and storage

Packaging was stretch film, vacuum packs in polyamide or polyethylene bags and kraft paper with plastic stretch film covering only the core, as with custom-cut cheese.

Ripening and storage in the above most commonly used forms of packaging allowed a decrease in L. monocytogenes in raw milk Cantal type cheeses after 45 days of ripening.

Cantal cheeses are ripened for 30 days to more than one year. Salers and Laguiole cheeses are only produced with raw milk, whereas Cantal can be produced with raw or pasteurized milk.

Whatever the weight of the cheese, L. monocytogenes increased during the first 24 hours of cheese making and decreased in cores and rinds during ripening at 9 °C from day 45 to day 360.

Acids were measured to help explain the decrease in L. monocytogenes during ripening in the study.

During ripening, cheeses were sampled at 11 stages: at days 7, 14, 30, 45, 60, 90, 120, 180, 210, 240 and 360, and in two different places to take into account the heterogeneity.

For each batch, the cheeses were cut and packaged at seven different stages of ripening: 30, 60, 90, 120, 180, 210 and 240 days.

Three packaging systems were chosen: stretch film (SF) (300g portions wrapped in plastic stretch film), Vacuum packs (V) (300g portions vacuum packaged in Polyamide (PA) or Polyethylene (PE) bags) and Kraft Paper (KP) (1/8 cheese wrapped in Kraft Paper, with plastic stretch film covering only the core, as with custom-cut cheese).

Film-wrapped cheese portions were kept for 21 days, while vacuum packed and kraft wrapped portions were held for 45 days, corresponding to maximum best use before date (BUBD) indicators by cheese operators.

L. monocytogenes behaviour

L. monocytogenes increased during the first five hours and reached a level of 2.5 log CFU/g, due to growth and concentration by curding.

It reached its maximum of 3.5 log CFU/g at the end of the draining step (24 hours). It stopped growing during milling and salting and then stabilized or decreased slightly until day three.

Between days 3 and 45, levels in the cores remained constant at between 3 and 3.5 log CFU/g with no significant difference between the two cheese weights (10 kg or 40 kg) or between the two milk batches

However, it was significantly lower in the rinds than in the cores, beginning to decrease earlier in the rinds (day 30) than in the cores (day 45).

During the second phase, from day 45 to day 360, L. monocytogenes decreased in the cores and the rinds.

Cheese rinds and cores

In the rind of cheese portions packaged under vacuum or in stretch film at different stages of ripening, the level of the pathogen remained stable.

For portions in kraft paper, a decrease was observed for cheeses packaged at 30 days, 90 days and 120 days.

After 45 days of storage, L. monocytogenes was lower in kraft-wrapped cheese than in vacuum-packed cheese, in cheeses ripened for 60, 90 or 120 days (more than 1.3 log of difference).

In the cheese cores, whatever the packaging, L. monocytogenes decreased significantly in cheese portions wrapped at 30, 60, 90 and 120 days of ripening.

The study was supported by FEDER and FNADT, Auvergne region, Cantal and Aveyron departments funding and by the three Protected Designation of Origin (PDO) cheese sectors.

Source: Food Control Volume 54, August 2015, Pages 53–65

“Behaviour of Listeria monocytogenes in raw milk Cantal type cheeses during cheese making, ripening and storage in different packaging conditions”

Online ahead of print, DOI: 10.1016/j.foodcont.2015.01.007

Authors: C. Chatelard-Chauvin, F. Pelissier, S. Hulin, M.C. Montel