New eco-coating to replace plastic packaging films

CaiLar can be used in place of oil-based plastic films as a moisture-resistant barrier coating for cardboard and paper packaging, said researchers from the joint project between the UK’s Sheffield Hallam University (SHU) and Karlstad University in Sweden. The product will initially be aimed at low-water content foodstuffs, such as biscuits and perhaps cheese.

The coating was developed as part of Sustainpack – a European research programme to encourage the use of traditional natural based packaging products. It recently scooped third prize at the Innovators Contest at Globe Forum 2010 in Stockholm.

"Consumption is increasing in society and it is increasingly important to find replacement materials for the plastic films that dominate today's packages,” Professor Chris Breen, head of SHU’s Polymers, Nanocomposites and Modelling Research Centre told FoodProductionDaily.com. “The fact that there is a good supply of raw material and that large-scale production is easily achievable are important factors - and there are added benefits from a recycling viewpoint.”

Coating properties

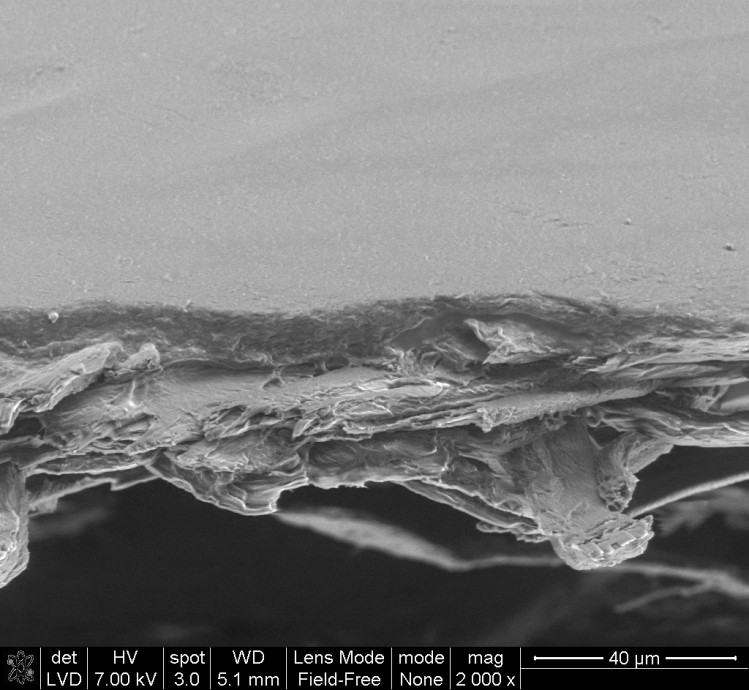

The team explored a wide number of starches and clays in order to find a suitable combination of materials. One challenge was to overcome the brittleness of starch, which is exacerbated by the addition of clay.

“Consequently, as with all starch coatings, we had to also identify a suitable plasticiser which was safe for food contact,” said Prof Breen. “It is the synergistic interaction between clay, starch and plasticiser which provides the excellent barrier properties to moisture.”

He explained that a board substrate without any coating had a water vapour transmission rate (WVTR) of 340g per square meter per day. Adding two individual layers of the starch and plasticiser reduced the WVTR to 260g per square meter per day. The step-change came with the incorporation of clay into the two-layer coating which saw the WVTR value drop to 30g per square meter per day. The measurements were made at 23°C and 50 per cent relative humidity.

Commercialisation

The team also found the optimum clay-starch-plasticiser combination that would maximise moisture and oxygen barrier properties. Under normal conditions, starch’s oxygen barrier properties plummet in the presence of moisture, added Prof Breen.

The group said it is seeking partners for scaling up the coating and plan to finalise a commercialization strategy by the end of next month.

All the coating components are on the white list and the group has yet to seek regulatory approval. A patent protecting intellectual property rights has been submitted and the application is currently going through a patent cooperation treaty application, he added.