Peco InspX partners with Valcour Process Technologies for distribution of cheese X-ray systems

Headquartered in San Carlos, California, Peco InspX Corporation serves customers around the world and inspects more than 120m food and beverage containers daily.

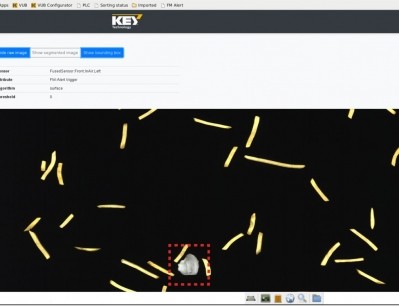

According to Peco-InspX, X-ray systems provide better foreign material detection in all forms of cheese (plastic tubs, bags and small and large blocks), and can find smaller pieces of metal in large cheese blocks than the most sensitive metal detector.

Consistent detection

Typical X-ray system detection for a 40 lb block of cheese will be approximately 1.5-2.0mm 304 stainless steel, whereas the corresponding minimum size for a metal detector will likely be 6.0mm, the company said.

Peco InspX said its imaging reduces “burn through” on the edges of the product, meaning consistent detection is achieved throughout the product.

False rejects are also eliminated on cheese that creates image noise (such as Swiss cheese) due to Peco’s software that “learns” product features.

Martin Lymn, vice-president for US sales, said the partnership with VPT underscores a strong commitment to “developing world-class solutions for the cheese industry.”

VPT, based in Peru, New York, specializes in the cheese production and converting market. It offers equipment, systems, and lines for cheese production, converting, packaging, and inspection applications.