Independent think tank RethinkX is predicting the most consequential disruption of food and agriculture in history.

According to the London- and San Francisco-based research institute, technology known as ‘precision fermentation’ is driving down the costs – and driving up the quality – of modern proteins.

By 2030, therefore, modern food products will be both cheaper and better quality than their animal-derived counterparts, RethinkX forecast in its recent report.

What is precision fermentation?

Precision fermentation is a technology that enables the programming of micro-organisms to produce complex organic molecules, such as proteins, at ‘a fraction of the cost’ we do now.

“This technology is not new,” according to RethinkX analyst Catherine Tubb. “It has been…disrupting protein for four years, and we have been moving down the cost curve.”

This is largely due to improvements in biological and information technologies: whereas it used to cost $1m (€903k) to produce a kilogram of one type of molecule in 2000, technological advancements have reduced that cost to around $100 today.

“By 2025, we forecast that we’re going to be cost competitive with bulk animal protein,” said Tubb at the Westminster Food & Nutrition Forum in London this month, which stands at around $10 per kg for casein and whey.

RethinkX expects these costs to fall below $10 per kg by 2025, before becoming five times cheaper than traditional animal proteins by 2030, and 10 times cheaper by 2035.

Disruption of the cow

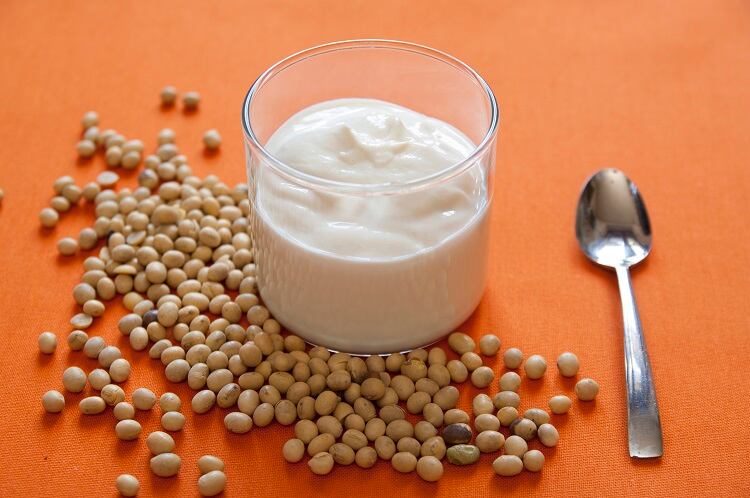

So how will precision fermentation disrupt the dairy sector? According to RethinkX, the answer lies in replacing just 3.3% of milk’s content. This small percentage of key functional protein is all that need be substituted by precision fermentation-derived ingredients to collapse the industry.

“This is an ingredients-led business to business disruption,” Tubb explained, stressing that the model does not rely on a change in consumer behaviour. Rather, food manufacturers will purchase milk – or milk powder – made ‘cheaper, faster, and with fewer inputs’ than conventional dairy.

The demand is there. “Nestle, for example, buys almost 2% of global dairy production,” said Tubb, adding that “Quorn [also] uses protein in their products.”

As is the current supply: “We know that about 35% of dairy protein in the US ends up in the B2B market…and about 70% of the New Zealand dairy market is made into solids and exported.”

The implication is that industrial cattle farming, and all livestock farming, will be obsolete by 2035, Tubb continued. “Precision fermentation is going to outperform the cow.”

‘Anywhere you can brew beer, you can make food’

Looking beyond the collapse of the dairy sector, precision fermentation technology has the potential to transform and decentralise the food system.

“Anywhere you can brew beer, you can make food,” said Tubb, suggesting that today’s centralised food systems could be transformed into local, network-focused production.

The implications of precision fermentation are therefore ‘massive’ and ‘profound’, spanning environmental, economic, social, investment, and geopolitical sectors.

In the not-so-distant future, we may see fermentation tanks incorporated into the urban landscape, whether they be positioned ‘on top of Ikea’ or stacked on supermarket roofs.

Food costs are also predicted to drop. RethinkX predicts fermented foods will be priced at least 50%, and as much as 80%, lower than the animal products they replace.

Its environmental benefits are another key argument for precision fermentation technology. These ingredients will be up to 100 times more land efficient, 10-25 times more feedstock efficient, 20 times more time efficient, and 10 times more water efficient than industrial livestock, noted the think tank. “They will also produce an order of magnitude less waste.”

So what could stop us getting there? The barrier to adoption may well be the current food system itself, Tubb suggested. How will we regulate a new, modernised food system under the current regulatory framework?

This disruption is ‘inevitable’, however its regulatory pathway is ‘not predetermined’, she continued. What is sure, is that if the UK does not seize this opportunity, ‘other countries will’.