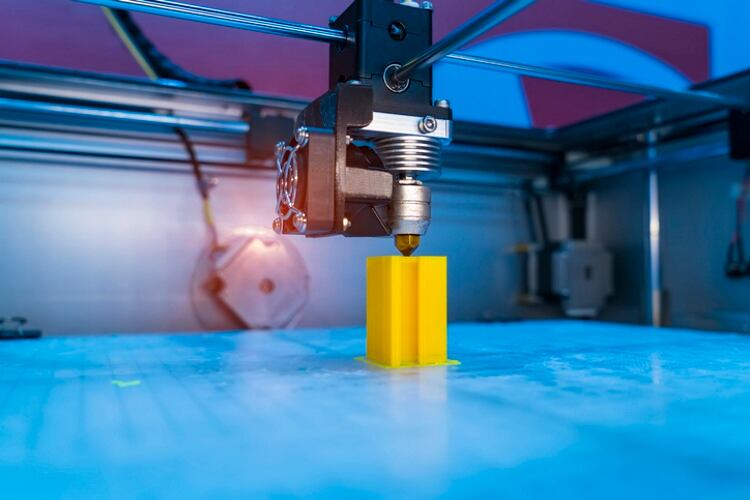

The SUTD team developed a method to perform direct ink writing (DIW) 3D printing of milk products at room temperature by changing the rheological properties of the printing ink.

The research was published in the RSC Advances journal.

3D printing of food products has been demonstrated by different methods such as selective laser sintering (SLS) and hot-melt extrusion. Methods requiring high temperatures are, however, not suitable to creating 3D models consisting of temperature-sensitive nutrients. Milk is an example of such foods rich in nutrients such as calcium and protein that would be temperature sensitive.

Cold-extrusion is an alternative method of 3D printing, but it requires the addition of rheology modifiers and the optimization of the multiple components.

To address this limitation, the researchers demonstrated DIW 3D printing of milk by cold-extrusion with a formulation of the milk ink. The method relies on only one product, powdered milk. The scientists formulated 70 w/w% milk ink and successfully fabricated complex 3D structures.

They also demonstrated multi-material printing and created food with various edible materials.

Given the versatility of the demonstrated method, the authors of the paper envision that cold extrusion of food inks will be applied in creating nutritious and visually appealing food, with potential applications in formulating foods with various needs for nutrition and materials properties, where food inks could be extruded at room temperature without compromising the nutrients that would be degraded at elevated temperatures.

The authors said 3D food printing allows customizing nutrients based on individual needs, fabricating aesthetically pleasing food, and modifying internal structures of the food. They add that their work will contribute to unlock the full potential of 3D printing of foods such as customization of texture and personalization of nutrition.

3D printing of milk-based product

Cheng Pau Lee, Rahul Karyappa and Michinao Hashimoto

RSC (Royal Society of Chemistry) Advances