However, r-PET (recycled polyethylene) is readily available through existing bottle recycling streams, but has so far been largely unsuitable for dairy packaging due to its material properties.

Where high temperature sterilization (HTS) is required, PET has to withstand temperatures of up to 120°C. With initial tests for the use of r-PET HTS in packaging for dairy products, Greiner Packaging is expanding its material competence and adding another component.

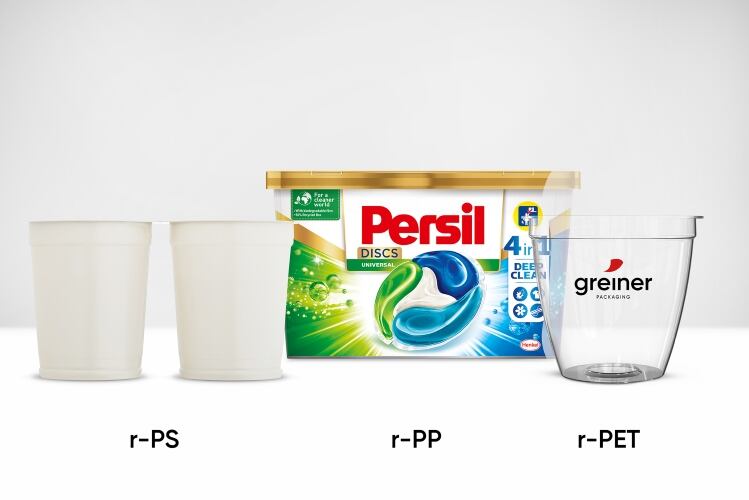

At the moment, r-PET is the only food-approved recycled material, while r-PS and r-PP are still in the test and approval phase. It is therefore important to provide dairies with a recycled material that can withstand the necessary production processes.

Greiner Packaging said crystalline-PET (CPET) does not represent a solution for the dairy market. While it can withstand hot sterilization of up to 240°C, the nucleating agents contained in it make recycling difficult.

A distinction is generally made between mechanical and chemical recycling of r-materials. The former has a better carbon footprint, while the latter enables dirty yet valuable material or composite material to be recyclable. Although the chemical process is a little more complicated, the quality of the product is comparable to virgin material, which means approval for its use in food packaging is assured.

Mechanically recycled PET is available in relatively large quantities from the material cycle, which means new plastic products can be manufactured from up to 100% mechanically recycled PET for use in the food industry.

Tests are currently under way for the dairy industry to see how PET can tolerate temperatures of up to 120oC during HTS. The main focus will be on how the current sterilization process can be compatible with hydrogen peroxide. The aim is to ensure dairies are not forced to make changes to the filling process when using material such as r-PET.

Greiner Packaging said it is working with its dairy customers on this process.

“We are also in the process of finding an alternative to the PET bottle stream. Obtaining recycled material from different sources would mean us no longer being solely dependent on bottle flakes in the medium and long term. We are currently evaluating different sources and opportunities, as well as having discussions with a number of suppliers who can offer social PET. One example is our work with Plastic Bank,” Jörg Sabo, global marketing and innovation director at Greiner Packaging, said.

Mechanically recycled PP can currently only be used for non-food packaging, however a food approval is in preparation. Chemically recycled PP is suitable for food contact, but not readily available as there are no large-scale recycling streams for PP. Greiner Packaging is currently involved in a project that aims to obtain food approval for r-PP from mechanical recycling.

Recycled PS is in short supply as a chemically and mechanically recycled material. Here too, recycling streams must first be established. However, earlier tests have already shown the high purity content of PS makes it ideally suited to mechanical recycling.

Initial tests in Switzerland have shown Greiner Packaging is capable of producing yogurt containers made from 100% r-PS material. For the first time, 100% mechanically recycled PS was used with 100% recycled cardboard in a joint project with M-Industry.

The process was tested for Swiss K3 twin yogurt packs. Greiner Packaging said the results were promising. None of those involved in the test noticed any sensory deviation as a result of the new, first-time use of r-PS material. The process for obtaining certification of r-PS for use in yogurt containers is already under way in Switzerland.