The technology prevents entire pallets from becoming contaminated by individual bag leaks, which were previously responsible for high product-recall costs. Greif-Velox said it is the first manufacturer to offer this type of optical measurement system.

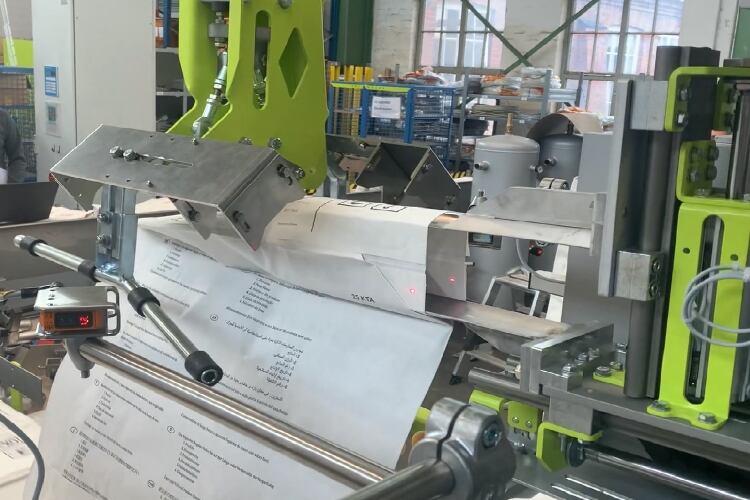

ValvoDetect checks whether a bag is properly sealed at two separate points in the filling process. First, it uses sensors before the bag is filled to verify whether the bag has been correctly positioned or whether there is an issue due to an error in the valve opening step.

A second check, using optical sensors, takes place before the sealing step. If the bag is not correctly positioned in relation to the welding sonotrodes, it could result in a faulty seal. WIth ValvoDetect, only properly sealed bags make it onto the pallet. This ensures there is no product leakage and prevents contamination and serious consequences, such as pest infestations in food products.

ValvoDetect also gives users saving potential, the company said, noting it delivers a near-total return on investment through the ValvoDetect alone, and lowers complaint and recall rate to boost a company’s market reputation.

“With ValvoDetect, our customers can achieve maximum process efficiency and more end customer satisfaction,” said Dr Alexander Mildner, head of research and development at Greif-Velox.