Today, consumers want it all when enjoying dairy products like yogurts: a smooth, thick texture; a healthy, sustainable label; and a fair price.

However, this means dairy manufacturers are under high pressure to cut costs, reduce waste, and keep labels short and sweet. But potato starch could be the surprising answer to these challenges.

Meleknur Tüzün, Global Segment Manager Dairy at Avebe, shares her evidence-based insights on how to create dairy products using potato starch that are creamy, clean-label, and cost-effective.

“Consumers expect dairy products like yogurt to be both indulgent and healthy, so they’re often disappointed if the texture feels thin, watery, pulpy, or overly pudding-like,” says Tüzün.

Ingredient volatility is a key concern for dairy producers. Milk fat, in particular, is both costly and prone to price swings. Many teams try to reduce milk fat levels for health and cost reasons with alternatives like hydrocolloids or modified starches to achieve that desired creamy texture.

“But these ingredients don’t fit with popular clean-eating trends. They can seem artificial to customers, since they often appear alongside unfamiliar, technical-sounding ingredient names and E-numbers,” Tüzün adds.

Plus, hydrocolloids and modified starches can be tricky to use during dairy processing. They require precise handling conditions and can sometimes thicken or gel too early in the process. And they aren’t the most sustainable options.

Meanwhile, shelf-life issues like syneresis (water sitting on top of the yogurt) can trigger waste, complaints, and reworks, even if the product is safe to eat and the issue is purely cosmetic.

To tackle these challenges, the goal is to create decadent, cost-efficient dairy products that customers love, featuring simpler labels and seamless processes.

How does potato starch work in dairy applications?

“To meet market needs, we’ve built a texture toolbox based on research that helps us understand and unlock functionality such as creaminess and mouthfeel across a wide variety of dairy applications. Our solution: ETENIA®, a clean-label, multifunctional, 100% potato starch that behaves like a hydrocolloid with thermo-reversible gelling,” says Tüzün.

“This means that the gel melts when heated and sets again when cooled, without losing its texture. It has a neutral taste and appears on a product label simply as potato starch,” Tüzün adds.

ETENIA works well in dairy products like:

- Stirred, set, or drinking yogurt

- Puddings, desserts

- Fresh cheese spreads

Indulgence without compromising on health

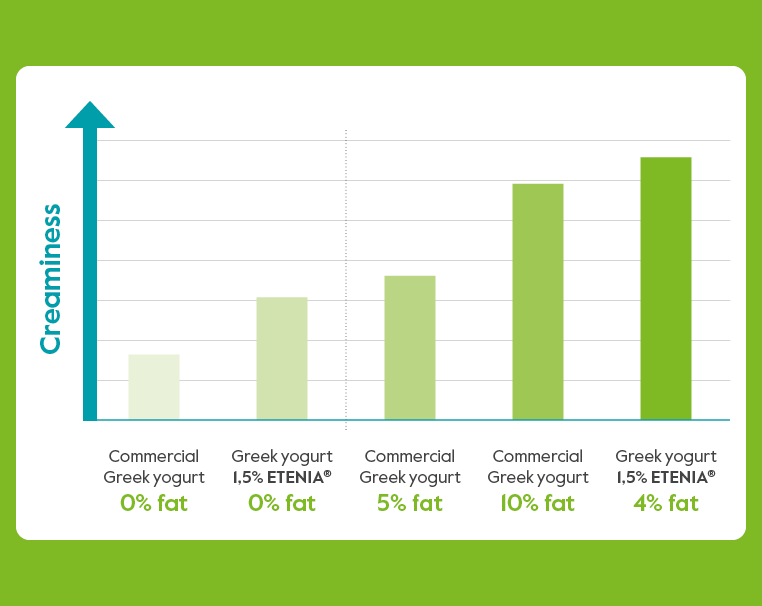

“Getting mouthfeel right in formulation is one of the biggest challenges in dairy. Through our work in texture science and a broad portfolio of solutions, we’ve identified approaches that consistently deliver consumer-preferred mouthfeel experiences. In our lab tests, we discovered a Greek-style yogurt with 0% fat and 1.5% ETENIA nearly doubled creaminess versus a commercial yogurt with 0% fat,” says Tüzün.

“And in another trial, a 4%-fat Greek-style yogurt with 1.5% ETENIA® beat commercial 5%- and 10%-fat yogurts on creaminess. The application of ETENIA boosts creaminess at low use levels,” Tüzün shares.

“Consumers want a dairy texture with a full creamy mouthfeel sensation. They’re not really open to changes in texture. Smoothness and creaminess are key drivers of product enjoyment,” Tüzün continues.

Using potato starch, brands can lower fat content without compromising on decadence, while maintaining the texture customers love and meeting health goals.

Cuts costs without canceling creaminess

Common dairy industry ingredients like butter, cream, and milk regularly fluctuate in price, making cost a main driving factor in the industry. Therefore, most producers look for ingredients with more stable pricing.

Tüzün explains, “According to our lab tests in dairy applications: 1% ETENIA can replace 3% milk fat; 1% ETENIA can replace 1% milk protein; and 1% ETENIA can replace 0.5% gelatin.”

Sustainable and clean-label

Replacing hydrocolloids and modified starches, 100% natural potato starch is certainly a sustainable ingredient to use.

”We asked an independent third-party consultant to test the sustainability profile of our products. The results showed that compared to formulas with the same textures, ETENIA better reduces total carbon footprint versus gelatin in yogurt applications and milk protein in cream-cheese-type applications,” Tüzün shares.

Shelf life and consumer appeal

Potato starch is a strong water binder and gelling starch that helps reduce syneresis. That means products appear fresh (and not liquid or watery) when customers lift the lid and stay stable until the very last spoonful.

“Plus, ETENIA helps yogurts appear bright and white, so the eating experience is pleasant, smooth, and ‘full-fat’ in sensation. That’s because potato starch mimics the behavior of milk fat in the mouth, without adding off notes. This matters for repeat customers, where even tiny textural differences can affect loyalty. A rich, creamy mouthfeel boosts overall liking scores for the end product,” explains Tüzün.

Operationally, lower syneresis and a more predictable production process help reduce waste and product rework, which in turn improves the overall sustainability of using potato starch.

Flexible and robust process

ETENIA’s texture forms after cooling, which is generally within 12 to 24 hours. This prevents mixtures from thickening or clogging during processing and gives manufacturers more freedom with their approach.

“Manufacturers need to forget what they know about typical starches, because ETENIA is different. It doesn’t adapt its texture on the line. Instead, it sets cleanly after cooling, which means it fits perfectly into high-temperature dairy processes without creating line issues.

“Likewise, with ETENIA, manufacturers can achieve their desired product texture by adjusting the use level and the process. To make this practical, we use a suite of solutions built on our benchmark toolbox. These address three recurring challenges in dairy: achieving creaminess, creating the right mouthfeel, and finding the perfect texture. With these tools, producers can fine-tune dosage, optimize preparation, and ensure consistency across processes and applications,” says Tüzün.

For example, here are some texture options:

- Firm yogurt profile

- Creamy Greek-style yogurt

- Spreadable cream cheese

Transform dairy products with potato starch

Potato starch gives dairy producers and manufacturers a practical, proven way to maintain an indulgent texture and mouthfeel, along with clean-label, cost control, and sustainability benefits. It raises creaminess at low use levels, replaces more expensive dairy solids, and simplifies processes, all while keeping taste pure and delicious and labels short.

“Potato starch can replace hydrocolloids or modified starches at the same function or even improved functionality. It can replace milk protein or milk fat. It can work in very harsh dairy conditions, in every process setting and can create different textures free-from allergen labeling.

“If you’re looking for the best protein or fat replacement, or to enhance creaminess in dairy applications, this multifunctional potato starch is one of the purest ingredients you can use,” Tüzün concludes.

For dairy products, where texture is everything, ETENIA transforms common constraints into a competitive advantage.

Learn more about making the switch to ETENIA clean-label potato starch here.