California Dairies Inc. advances supply chain decarbonization with 'largest' solar thermal systems and more

California Dairies, Inc. (CDI) is on track to reduce carbon emissions by more than 4,700 metric tons thanks to adopting new heat recovery and renewable heat systems at its largest facilities.

According to the Farm Carbon Toolkit, greenhouse gas (GHG) emissions from power and fuel use, mainly in the shape of carbon dioxide, typically account for about 10% of a dairy farm’s total. Enteric methane emitted from cattle and emissions associated with manure management (e.g ammonia and nitrous oxide) are the two main sources of GHG gases on-farm, with gasses from chemical fertilizer use and feedstuffs also contributing to the overall amount of emissions. However, emissions from power, fuel, water or transportation – so-called direct emissions, or scope 1 and scope 2 - are easier to quantity and remove compared to value-chain emissions (scope 3).

In its most recent sustainability report, CDI committed to removing 30% of its direct and supply chain GHGs by 2030. The dairy co-op is also assessing the environmental footprint of all its farms, a task that should be completed by the end of 2025 and would offer insight into emissions originating from the value chain (scope 3). As part of scope 1 and 2 emissions reductions, the co-op is aiming for 80% of on-farm electricity use to be ‘renewable or carbon-free’ by 2030 and for 70% of electricity to come from renewable sources by 2030. A recently-completed project in partnership with Skyven Technologies was a step towards achieving that.

CDI partnered with Skyven Technologies, a company that specializes in decarbonization strategy and implementation, to install three technologies designed to increase energy efficiency and reduce emissions at the co-operative’s two largest plants, in Visalia and Turlock (South).

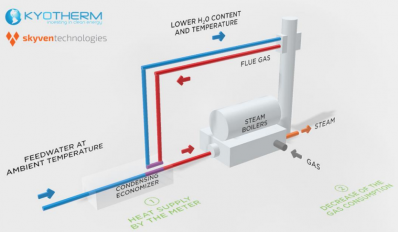

The three solutions include two solar thermal systems, which convert solar energy into heat for thermal processes; according to Skyven, these installations are among the largest globally. Also installed was a boiler heat recovery system designed to increase boiler efficiency by around 10%. Combined, the improvements have saved over 3,500 metric tons of CO2 and over 65,000 MMBtu of natural gas, which can grow to more than 4,700 metric tons of CO2 and over 89,000 MMBtu of natural gas over the course of a full year. A Skyven representative said: “The 3,500 metric tons of CO2 reduction from this project is significant for both CDI and the dairy industry as a whole. If all dairy processing facilities across the US implemented similar decarbonization projects, the dairy industry would reduce greenhouse gas emissions by over 1.4 million MT - this is equivalent to removing 311,542 gasoline powered cars from the road each year.”

The solar thermal systems are integrated with a smart steam trap that uses sensors connected to the Internet in order to monitor and reduce steam loss at each facility. Importantly, the carbon emissions savings would be quantifiable thanks to monitoring technology. This is particularly relevant at a time when the European Union has moved to ban claims of carbon neutrality that cannot be verified. “Skyven’s decarbonization solutions reduce CO2 emissions by decreasing natural gas consumption at industrial facilities,” the company told us. “Our emissions reduction claims are measured and verified with meters and IoT data monitoring. We provide data-backed carbon reporting and financial metrics in real time.”

Skyven also told us that the project was first of its kind in terms of the financial structure that was used. The project leverages grant funding from the California Energy Commission’s Food Production Investment Program (FPIP), utility incentive funding from Pacific Gas & Electric and Southern California Gas Company, third-party project finance, and investment from Skyven’s balance sheet. “The above project structure allowed the integrated decarbonization technologies to pay for themselves from the resulting energy savings, meaning no capital outlay was required from CDI,” a Skyven representative explained.