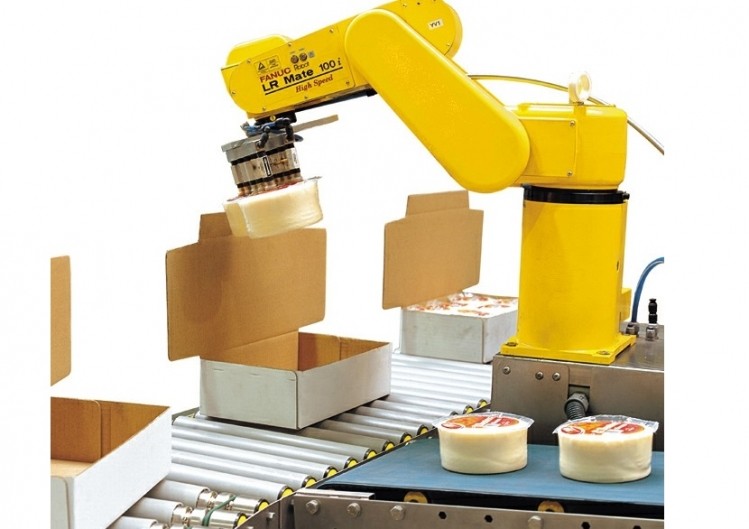

Fanuc: robots can boost yield in dairy factories

The company said a rise of smaller dairy snack foods and variety multi-packs (such as a number of different yogurt flavours in a pack) is encouraging the use of robots in dairy production environments.

Pick and place robots – which pick up items and place them in a different location – boost product yield and improve labour efficiency, the company claims.

Flexible robots

John Rainer, regional sales manager, FANUC, told DairyReporter.com robots show advantages when a factory produces a number of different products.

“If you’re only going to run one product, you wouldn’t necessarily look a robot. If you’re going to run yogurt pots one day, sour cream the next, different sizes, different shapes, then flexible automation starts to win out.”

Rainer said tasks which had once been deemed best to be performed by hand can now be picked up by some of the more flexible robots on the market.

Fanuc is also seeing a requirement for robots which can handle a variety of packs. To meet this, they can be fitted with different interchangeable end tools including gripper, vacuum, magnet and clam-shell styles.

The answer to dealing with more delicate products – such as yogurts or fine cheeses – comes with the programming, Rainer said.

“It’s not so much a case of being sensitive, as doing the right thing at the right time,” he explained. “A robot could come down and flatten a pot of yogurt. Instead, it goes to the appropriate place and grips it, and does what it should do.

“It also comes down to making sure the correct pot has arrived [on the production line]. You don’t change from a 150ml pot to 300ml without telling the robot.”

IP69K certification

Robots are also becoming more common in dairy production sites because they meet IP69K certification, which refers to the resistance and protection against high pressure water. This means it can be washed down to maintain sanitary conditions.

Fundamentally, there is little difference to a robot in a dairy factory than any other production facility, Rainer said. However, environmental factors - such as dust or liquid - need to be considered, and the IP69K also certifies a level of resistance against dust.

Robots can be used in chilled environments, Rainer added.

FANUC pick and place robots will be on display at the PPMA (Processing and Packaging Machinery Association) show, September 30 to October 2, in Birmingham, UK.