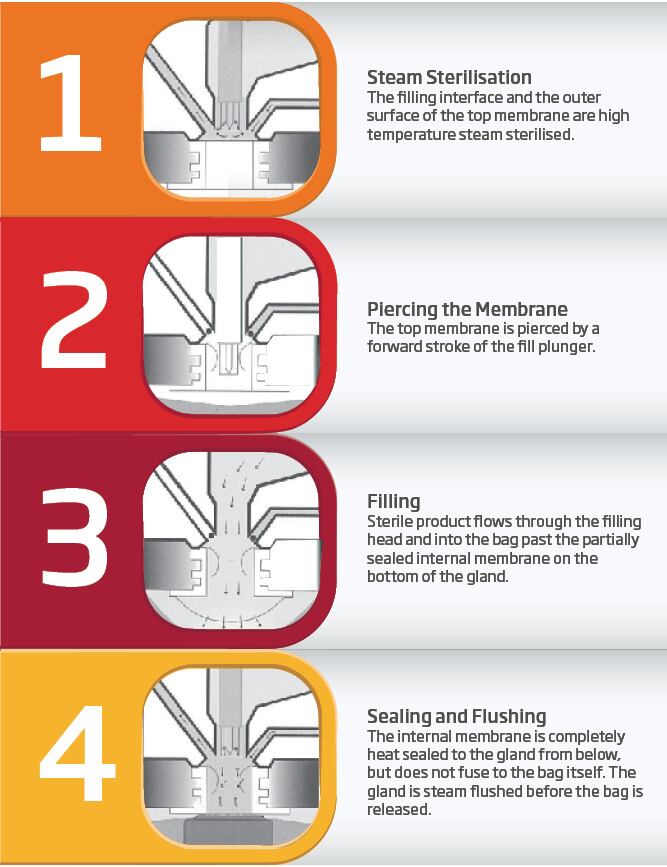

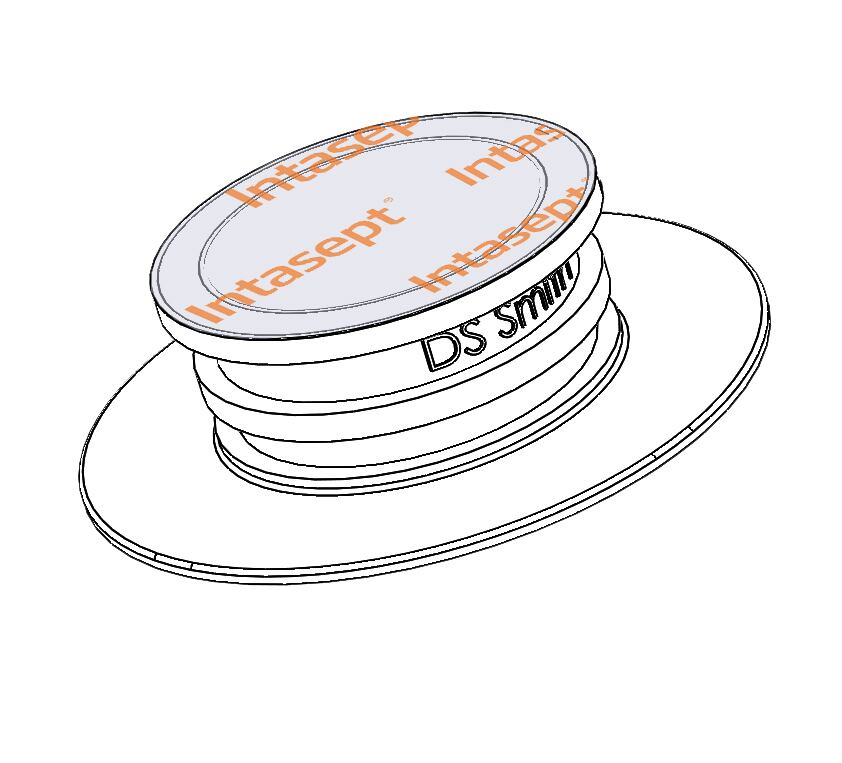

The technology offers a heat-sealed closure before and after filling using a double membrane gland, which is available in 32mm and 16mm formats.

Active ingredients

Intasept’s aseptic system is suitable for liquid and particulate foods and beverages including milk, juices, coffee, tea, ice cream mix, creams, custards, puddings, soups, broths, sauces, fruit and vegetables purees and pulp.

According to Rapak, Bag-in-Box for functional foods is one of the areas in which growth is expected for this packaging format.

Intasept aseptic filling technology in Bag-in-Box can be used to supply active ingredients such as Omega 3 and vitamins that are added to dairy or other products.

"There are two main applications in functional food," said Anastasia Khodakova, marketing manager, Rapak Europe.

"The first is for ingredients, e.g. a producer will use an Intasept system to pack and transfer vitamins, minerals and other nutrients that are added to basic products. This is growing as there is a clear trend for products like enriched dairy (e.g. milk with vitamins, Omega 3 etc) and juice.

"Another application is clinical feeding for hospitals which is mostly functional food for people with specific dietary needs and meal replacements for patients.

"Apart from that Intasept can be used for any liquid food in foodservice such as creams, sauces, purees, soups etc."

Since Intasept was introduced to the market by Rapak it claims the aseptic part of the business has grown to 12% of total Bag-in-Box European sales.

The aseptic Bag-in-Box market in Europe is estimated at 62m liters because the packaging format caters to new product categories.

Flexible bags

Rapak launched its next generation 32mm Intasept gland for Bag-in-Box in 2013 because it offers a more effective seal of a flexible bag.

Its Bag-in-Box fillers are available in semi-automatic and fully automatic options for 1-20 liter bags and bulk containers, which can seal low and high acid products without using any chemical sterilizing agents.