Greiner Packaging has worked with the dairy company to develop a packaging solution for the yogurt – a cup that reduces the use of plastic. The packaging manufacturer is now producing this solution as well, allowing it to respond to the market’s requirements and the trend toward lightweight packaging decorated with in-mold labeling (IML) technology.

Greiner Packaging achieved a material saving of 20% for the new plastic cup for the Greek yogurt, having reduced the solution’s weight by making adjustments in production.

The company said this has no impact on the functionality of the cup or its suitability for logistics and filling line systems. It added that separating the empty cups and stacking the sealed cups filled with yogurt are similarly unaffected. Also, the carbon footprint from transport is reduced due to the decreased weight of the cup.

The polypropylene (PP) plastic used in the cups is designed to be suitable for filling with dairy products and other foods in a refrigerated environment or at room temperature.

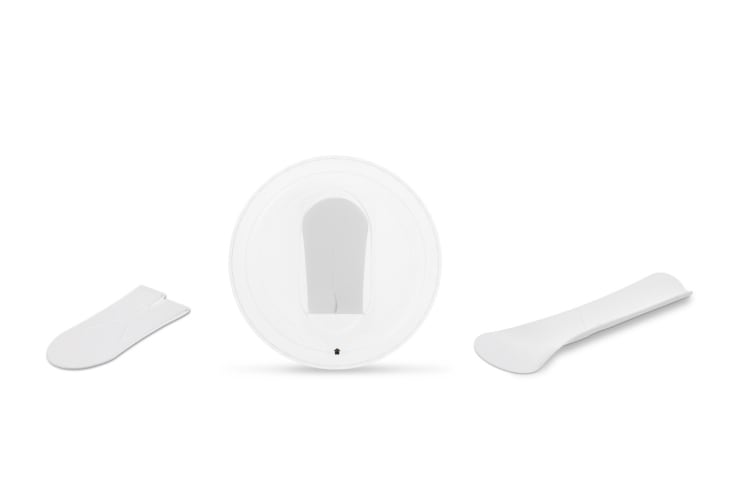

Greiner Packaging said the PP cup also offers design advantages. The IML technology – the use of a label fused with the cup during the production process – allows for a tailored brand identity with the same quality as photo printing.

Double-sided or interactive labels can be used: a QR code or digital watermark, for example, can be integrated for competitions, promotions, or similar consumer engagement activities. Plus, a range of surface effects is available to enhance the product’s look, including soft touch, matte, ultra-glossy, metallic, transparent, or imitation paper finishes.

As part of its efforts to utilize more renewable materials, Greiner Packaging also offers its customers biocircular plastics on request, such as those made from agricultural production waste. Because Greiner Packaging is ISCC Plus certified (International Sustainability and Carbon Certification), the company’s customers can highlight this on their packaging solutions if their organizations are also certified as part of the value chain. In addition, customers can use sealing film made of polypropylene so the cup, IML label, and sealing film are made of the same material. This represents a further step ahead in terms of recyclability.

“The new, lighter-weight IML cup for Greek yogurt is a great example of Greiner Packaging’s dedication to reducing material usage and the weight and carbon savings that come with it. The fact that we also make products from renewable materials on request, which in turn are 100% recyclable, is completely in line with our sustainable mindset and our mission to actively advance the transition to a circular economy,” said Philipp Maurer, key account and IML category manager at Greiner Packaging.

The company said it aims to produce packaging with the same functionality as previous solutions, but with improved recyclability, in order to cut back on plastic from virgin materials as well as reduce carbon emissions.