We chatted with Claus Bukbjerg Andersen, senior category manager at Arla Foods Ingredients; Andy Dwivedi, sales director at Evergreen Packaging; Prof. Ariel Kushmaro, from the Laboratory of Environmental Biotechnology and Avram and Stella Goldstein-Goren Department of Biotechnology Engineering at Israel’s BGU, and what may well be a first for the podcast, one interview with three people: John Talbot, CEO of the California Milk Advisory Board, Fred Schonenberg, CEO and founder of VentureFuel, and Jessica Levison, founder and CEO of Peekaboo.

We also have our weekly look at the global dairy markets with Liam Fenton from StoneX.

New servo driven half-gallon gable top packaging machine launched by Evergreen Packaging

Evergreen Packaging Equipment debuted its new servo driven EH-84 gable top packaging machine at the Virtual Pack Expo Show, November 9 to 13.

Designed to meet the needs of the dairy, juice and liquid food markets, the EH-84 can handle fill volumes of 40 ounces up to 2 liters, at speeds up to 8,400 cph (cartons per hour). Allen-Bradley PLC controls and servo driven technology provide repeatable package performance and automatically control fill volumes and profiles based on product and carton size. Infinite fill capability allows for less downtime with quick and easy changes in carton size or product.

The EH-84 has a high visibility of components and machine operation, as well as easily accessible areas reducing maintenance time. The infeed’s ergonomic design provides operator comfort and ease of loading. An optional SPOUT-PAK System is available to enhance consumer convenience and preserve product freshness.

Shelf life optimization features include ELL (Extended Long Life) components including a self-contained CIP/SIP system, environmental control features, carton decontamination and a hermetic fill system to maintain product quality.

As with all Evergreen Packaging gable top machines, the EH-84 is backed by 24/7 OEM parts and technical service to fulfill customer needs.

Arla Foods Ingredients launches organic solution for cooking-stable cheese

Arla Foods Ingredients has launched a new organic functional solution for cooking-stable cheese products.

The solution is part of a new line the company said helps manufacturers meet the growing demand for healthy, natural and organic products.

According to Innova Market Insights, organic cheese launches are growing at a CAGR of 15.1% in Europe, and a Lindbergh International study showed 73% of European consumers would buy more organic dairy products if they were more widely available.

Meanwhile, cooking-stable cheese products – such as grilling cheeses and cheese fries – are increasingly prevalent. Arla Foods ingredients said the products are a protein-rich substitute for meat, and have created new possibilities to cater for the growing number of vegetarian and flexitarian consumers.

Arla Foods Ingredients is now adding an organic line to its Nutrilac range of functional protein solutions, which offer multiple functionalities in dairy, including improved taste, texture, creaminess and stability.

The line includes Nutrilac FO-7922 Organic – a new product for cooking-stable cheese products. The company said it is suitable for grilling cheeses, cheese patties for burgers, cheese sticks, cheese nuggets and cheeses for hot pot soup, and it can also be used to create recombined dairy products.

As well as being organic, Nutrilac FO-7922 Organic is heat-stable in processing, allows flexible levels of sodium content and has a pleasant taste. Other advantages include 100% yield.

Claus Bukbjerg Andersen, senior category manager at Arla Foods Ingredients, said, “Contemporary ways of cooking and eating cheese are increasingly varied, and there’s demand for cooking-stable products in a variety of forms.

“At the same time, ethical purchasing drivers are increasingly important and the demand for organic products is huge. Our new solution meets all of these current market needs. It combines functional benefits with a natural, wholesome, organic positioning that boosts consumer appeal.”

BGN Technologies and ECOIBÉRIA to study bacterial biodegradation of PET

BGN Technologies, a technology transfer company of Ben-Gurion University of the Negev (BGU) in Israel, has announced it has signed a research collaboration agreement with Portuguese plastic recycling company ECOIBÉRIA.

The agreement covers the field of plastic recycling by bacteria, based on research from the team of Prof. Ariel Kushmaro and Prof. Alex Sivan, both from the Laboratory of Environmental Biotechnology and Avram and Stella Goldstein-Goren Department of Biotechnology Engineering at BGU.

Polyethylene terephthalate (PET) is the most abundantly used polymer in the world. It is estimated about 56m tons of PET are produced yearly worldwide, mostly as single use packaging material. Therefore, intense efforts are directed towards recycling and reuse of the PET plastic materials.

Kushmaro, Sivan and their team have been studying plastic biodegradation and have discovered several bacteria species able to biodegrade polyethylene, which was previously considered non-biodegradable, mainly because of the highly stable carbon-carbon bonds of the polymer backbone.

Based on the findings, the research collaboration project will assess the biodegradation of PET by previously-identified bacteria as well as novel ones, with the aim of developing a biodegradation process of PET whose products will be used as raw materials for recycled PET in the future.

"Plastic-containing products is one of the biggest environmental challenges facing modern society, and degradation and recycling of plastic are one crucial strategy for dealing with the environmental impact of PET," Kushmaro said.

"Existing technologies, such as thermo-mechanical recycling impair the mechanical properties of the polymer and suffer from other disadvantages such as the need for organic solvents, high reaction temperatures and intensive waste sorting. Bacterial degradation of PET into recyclable materials that can be then reused to manufacture new PET products is therefore a promising strategy that can have a global environmental and economic impact."

Jorge Lemos, CEO at ECOIBÉRIA, said, "ECOIBÉRIA's mission is to guarantee the sustainability of the production and consumption models and assist in the transition from the linear economy to the circular economy, through the transformation of PET plastic waste into valuable secondary raw materials.

"We believe that BGU's innovations in the field of bacterial biodegradation of PET complements our technologies and has the potential to become an important contribution to our plastic recycling efforts."

Based in the north of Portugal, ECOIBÉRIA is dedicated to PET plastic waste recycling. It is a producer of secondary raw materials such as PET flakes and, from April 2021, PET pellets. Every year around 50,000 tons of PET plastic waste is processed by ECOIBÉRIA.

BGN Technologies is the technology transfer company of Ben-Gurion University, the third largest university in Israel. BGN Technologies brings technological innovations from the lab to the market and fosters research collaborations and entrepreneurship among researchers and students. To date, BGN Technologies has established more than 100 start-up companies in biotech, hi-tech, and cleantech, and has initiated technology hubs, incubators, and accelerators.

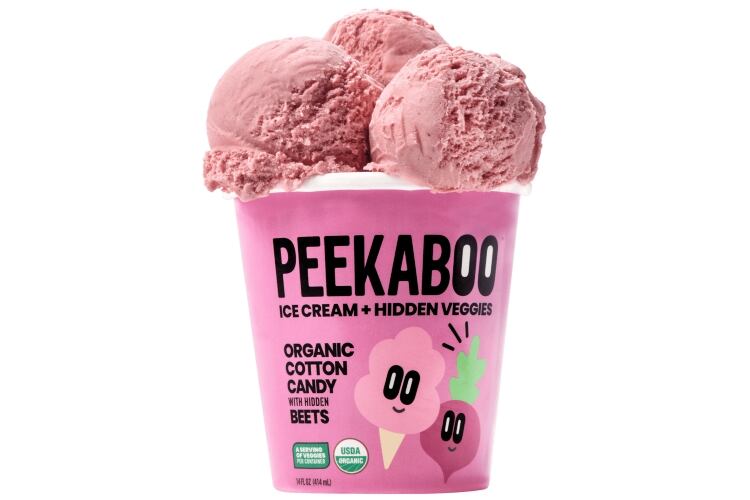

Peekaboo Organics ice cream with hidden veggies wins $200,000 at Real California Milk Snackcelerator

Peekaboo Organics’ ice cream featuring hidden vegetables was named the grand prize winner of the Real California Milk Snackcelerator dairy snack innovation competition created by the California Milk Advisory Board (CMAB) and VentureFuel.

The competition will provide Peekaboo with $200,000 in resources and funding to bring a snack-sized version of its products to market and expand the overall market for its products.

This is the second event of its kind by the California dairy industry designed to inspire ideas integrating the values of fluid milk and dairy ingredients into snacks to meet growing consumer demand and providing resources to help bring them to market.

As presented by founder and CEO, Jessica Levison, Peekaboo’s mission is to solve the parental dilemma of getting children to consume more vegetables by putting them into a format they can’t get enough of – ice cream.

As the owner of an ice cream scoop shop in Miami, she turned her frozen dairy knowhow into ice creams hiding nutritious vegetables. The products are currently available in pints at select retailers but Levison is looking forward to introducing the single serve snack line and expanding distribution with Real California Milk at the core.

"Like many of our fellow startups, we confronted what seemed like insurmountable challenges this year. This win validates our innovation, our mission and our team's hard work and resilience,” said Levison.

“We learned so much from this Snackcelerator experience and cannot wait to launch Peekaboo minis into the market – made with Real California Milk, of course! Much gratitude to everyone involved."

Alongside three other finalists, Peekaboo was judged on uniqueness or innovation, taste, the ability to scale and the founder team. Yummy Industries came in second place with its Cheese-Bits snacking cheese packs and will receive $100,000 in support for growth and distribution.

The Real California Milk Snackcelerator competition was designed to inspire innovation and investment in dairy based snack products, packaging and capacity within California by connecting manufacturers, producers, investors, ideas and entrepreneurs for sustainable products. The competition received 76 entries.

“This was a tough decision, all four of these finalists presented products that fit the needs of our current consumer and each with their own unique take on snacking. Peekaboo just had a slight edge because of its unique concept marrying two things that normally don’t go together like ice cream and vegetables and then executing the producer perfectly in terms of creative flavor combinations,” said John Talbot, CEO of the CMAB.

“Not only are we excited to grow the dairy snack portfolio offered with Real California Milk by helping to expand distribution for Peekaboo ice creams, we look forward to continuing our relationship with all of our finalists and semi-finalists to see what they are able to achieve.”

“Innovation is the ultimate growth accelerator for any business or category and this competition continues to deliver a flywheel of new ideas, new products and new ways to think about dairy from a consumer perspective,” said Fred Schonenberg, CEO and Founder of VentureFuel.

“When my family begged me for more samples between the semi-finals and finals, I knew we had chosen four winners all, of which can make an impact on-shelf. Peekaboo’s cotton-candy with beets flavor dominated the pre-judge chatter as one of the most delicious and unique desserts the judges had ever tasted, meanwhile Cheese-Bits was the product everyone was snacking on behind the scenes. They are making premium cheese easy to snack on and introducing new styles and flavors that will stand out.”