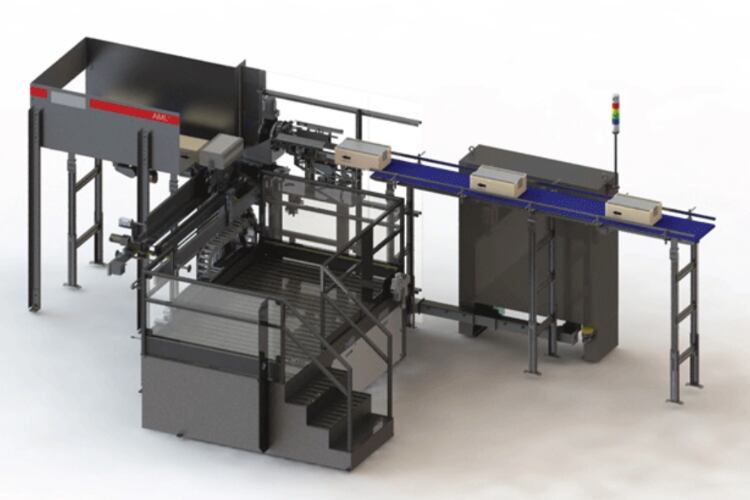

The company said the solution is modular in design, easy to use, and cost-effective, and enables manufacturers to implement labor-saving automated technology into the production line and increase output speeds within a small footprint.

The AML promotes cartoning-line efficiency by automatically pulling carton-filled cases off a conveyor and orienting them properly for loading. It then extracts the cartons from a case, loads them onto the magazine and disposes of the case.

The process minimizes the amount of time and interaction employees would typically dedicate to the loading stage of production, as they simply place cases in a queue for the conveyor and let the AML manage subsequent steps.

This allows manufacturers to reduce the number of employees required to run the line, which R.A Jones said is helpful given labor shortages and challenges in retaining production staff.

As an added benefit, the company said the technology eliminates the need for the human operator to pick up and rotate each individual case—a traditionally repetitive, injury prone motion. If the customer has additional floor space, an automatic depalletizer can also be supplied to fully automate the case-loading process. The result is a more positive, ergonomic work environment that limits strenuous activity.

R.A Jones’ AML technology includes proprietary carton correction technology that helps catch and reposition any cartons that might have fallen over at the end of the primed stack while it is moving along the magazine, preventing any related jams, bottlenecks and slowdowns. For a typical operation that may run 300 cartons a minute and must function continuously to meet heightened demand, this feature yields significant time and cost savings.

“The COVID-19 pandemic has created unprecedented challenges for manufacturers, asking them to meet elevated production levels with limited resources,” said Jeff Wintring, chief technology officer at R.A Jones.

“When a technology can help ease that pressure and do so in a way that also addresses important needs such as workplace safety, it becomes a gamechanger. We look forward to supporting our customers’ goals through our new AML technology and setting new standards for the cartoning industry.”

In addition to labor efficiency and employee safety, the AML provides a more manageable and cost-effective entry into automation for manufacturers challenged with justifying the implementation of a fully automated system, which typically requires significant capital investments and major line overhauls.

Unlike robotics-driven mechanisms that require greater floor space and a complex setup, the modular AML technology is a server-driven mechanism that fits within a smaller footprint and is operated via one integrated control system. This simplicity and flexibility allow manufacturers to draw from some of the key benefits of automation without investing in a fully automated setup, while still offering scalability for future production needs.

R.A Jones’ new AML technology is applicable to various CPG markets including food, facial tissue, household goods, and others.