We also have our weekly look at the global dairy markets with Liam Fenton at StoneX.

Clarity needed in classification systems for processed foods

Current food classification systems for processed foods lack consistency and consensus often leading to confusion and debate even amongst scientists, a new study in the journal Trends in Food Science & Technology, reports.

In the study, researchers from the University of Surrey and European Food Information Council (EUFIC) reviewed over 100 scientific papers to examine if different criteria exist in developing classification systems for processed foods and, if so, what distinguishes them. Classification systems that categorise foods according to their “level of processing” have been used to predict diet quality and health outcomes, inform guidelines and in product development.

Researchers found most classification systems’ criteria are not aligned with existing scientific evidence on nutrition and food processing. It is thought that this may stem from different perspectives and intentions behind the development of some classification systems.

Researchers also noted a failure to include measurements of nutritional content within some systems which may be confusing to consumers. The authors contrast this with nutrient profiling schemes such as Nutri-score, which converts the nutritional value of products into a simple code consisting of five letters.

Only a few of the classification systems examined in the analysis also acknowledge food processing done at home, and instead focus more on industrially processed foods. Researchers believe that this omission is misguided as food that is homemade is not automatically a healthier choice.

Categorization of foods deemed ‘ultra-processed’ and what is meant by the term, was also examined by researchers. While there is a lot of confusion and disagreement about the term, from the evidence available it is thought that these foods could relate to obesity by energy density and food properties such as texture. However, this will need confirmation through further research studies.

Christina Sadler, a postgraduate researcher and PhD candidate at the University of Surrey and a senior manager at EUFIC, who led the research, said, “We found that food processing and the degree of processing used are interpreted in different ways by different classification systems. It is concerning that there are no clear agreements on what features make food more or less processed, and how this relates to healthy eating advice, which may make it more difficult for consumers to make informed choices consistently.

“What is needed is clarification of the underlying methods, meanings and rationales of food classification systems so that foodstuffs can be classified consistently. This will help inform public health and ensure we eat a more balanced diet.”

Sadler, C. R., Grassby, T., Hart, K., Raats, M., Sokolović, M., & Timotijevic, L. (in press). Processed food classification: Conceptualisation and challenges Trends in Food Science and Technology.

Gelato company Bon AppéSweet wins Empower Project

The Empower Project, created by a consortium of 11 firms with the intention of amplifying the voices of Black-owned businesses in the consumer packaged goods space in the US, recently announced Bon AppéSweet, a maker of artisanal cane sugar-free gelato and chocolate bars as the winner of its first Power Pitch event.

The Empower Project team selected five finalists to move on to their Power Pitch event. In addition to Bon AppéSweet, finalists were Joe's Gourmet, Food + People, Ava's Pet Palace and Jimmy's Vegan.

Bon AppéSweet won access to almost $700,000 in professional services ranging from branding, marketing, communications, food manufacturing, e-commerce, financial strategy, start-up investing, financial strategy, data analysis, and legal assistance.

Bon AppéSweet, was founded by Thereasa Black, a naval officer, attorney, entrepreneur, and single mom. The idea for Bon AppéSweet came to her while she was serving in Djibouti. It was her fourth deployment, but the first since the birth of her daughter, Isabella, who recently turned two and fell in love with ice cream on their last night together. Throughout her deployment, Black dreamed of a way to never leave her daughter again. Giving up her promising future in law, she came up with the idea for Bon AppéSweet, a celebration of Isabella's love for ice cream.

"I knew when I left the military, I wanted to start a business. I also wanted an ice cream that I could allow my daughter to eat without feeling guilty, so Bon AppéSweet was born," Black said.

"There are so many potential pitfalls when launching a business and it's very hard for someone like me—a Black woman and single mother—to attract traditional financing. Participating in The Empower Project and then being chosen as the winner is truly a blessing. Knowing that I have the support and expertise of the sponsoring companies behind me allows me to breathe easier and move my business forward."

Black launched her business at farmers’ markets in July 2019, and the business took off from there with local retailers and via online. The Bon AppéSweet product line includes eight dairy-based gelato flavors (Banana Pudding, Chocolate Chip Cookies and Cream, Pistachio Swirl, Honey Butter Pecan, S'mores, We Woke [Chocolate Espresso), Milk Chocolate and Vanilla [Fior di Latte), and four vegan flavors using oat milk (Peach Cobbler, Butter Pecan, We Woke and Vanilla).

All are sweetened with fruit-based sweeteners as opposed to traditional cane sugar. Black also recently launched a line of dark chocolate bars made from organic dates, organic cocoa butter and organic cocoa powder.

"In the end, all of our finalists are winners, and we are excited to see what the future holds for each of them. Bon AppéSweet and Thereasa definitely stand out as a company and entrepreneur that we are eager to help scale," said Steve Gaither, chief marketing officer at C.A. Fortune who helped found the project alongside William Madden of Whole Brain Consulting.

"The Empower Project does not end here as there is still so much work that needs to be done. We look forward to continuing this program and helping to help amplify underrepresented voices within the space."

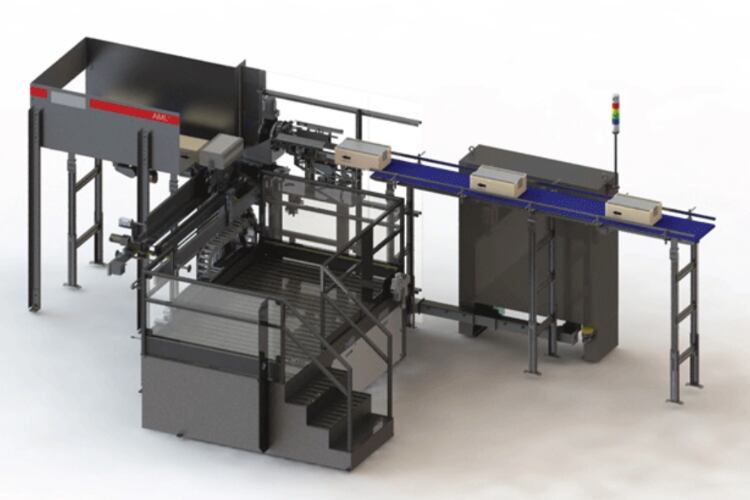

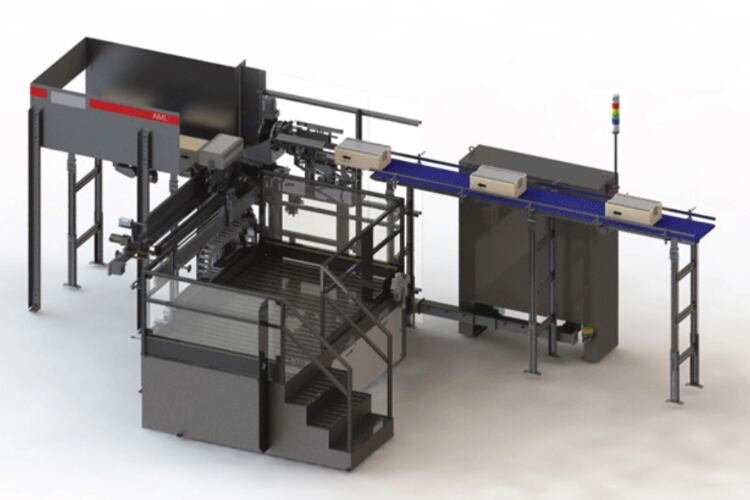

R.A Jones introduces automatic magazine loader for cartoning machines

To combat ongoing labor issues and meet surging demand for consumer-packaged goods throughout the coronavirus pandemic, US-based R.A Jones has designed and debuted an automatic magazine loader (AML) for use with its cartoning machines.

The company said the solution is modular in design, easy to use, and cost-effective, and enables manufacturers to implement labor-saving automated technology into the production line and increase output speeds within a small footprint.

The AML promotes cartooning-line efficiency by automatically pulling carton-filled cases off a conveyor and orienting them properly for loading. It then extracts the cartons from a case, loads them onto the magazine and disposes of the case.

The process minimizes the amount of time and interaction employees would typically dedicate to the loading stage of production, as they simply place cases in a queue for the conveyor and let the AML manage subsequent steps.

This allows manufacturers to reduce the number of employees required to run the line, which R.A Jones said is helpful given labor shortages and challenges in retaining production staff.

As an added benefit, the company said the technology eliminates the need for the human operator to pick up and rotate each individual case—a traditionally repetitive, injury prone motion. If the customer has additional floor space, an automatic depalletizer can also be supplied to fully automate the case-loading process. The result is a more positive, ergonomic work environment that limits strenuous activity.

R.A Jones’ AML technology includes proprietary carton correction technology that helps catch and reposition any cartons that might have fallen over at the end of the primed stack while it is moving along the magazine, preventing any related jams, bottlenecks and slowdowns. For a typical operation that may run 300 cartons a minute and must function continuously to meet heightened demand, this feature yields significant time and cost savings.

“The COVID-19 pandemic has created unprecedented challenges for manufacturers, asking them to meet elevated production levels with limited resources,” said Jeff Wintring, chief technology officer at R.A Jones.

“When a technology can help ease that pressure and do so in a way that also addresses important needs such as workplace safety, it becomes a gamechanger. We look forward to supporting our customers’ goals through our new AML technology and setting new standards for the cartoning industry.”

In addition to labor efficiency and employee safety, the AML provides a more manageable and cost-effective entry into automation for manufacturers challenged with justifying the implementation of a fully automated system, which typically requires significant capital investments and major line overhauls.

Unlike robotics-driven mechanisms that require greater floor space and a complex setup, the modular AML technology is a server-driven mechanism that fits within a smaller footprint and is operated via one integrated control system. This simplicity and flexibility allow manufacturers to draw from some of the key benefits of automation without investing in a fully automated setup, while still offering scalability for future production needs.

R.A Jones’ new AML technology is applicable to various CPG markets including food, facial tissue, household goods, and others.