As detailed in the study, 3D-printed microelectronics for integrated circuitry and passive wireless sensors, UC Berkeley engineers, working in collaboration with colleagues from Taiwan's National Chiao Tung University, printed a variety of electronic components, including inductors and capacitors, using a mix of polymers and wax.

The wax was removed, and silver was injected into the hollow spaces to create circuits.

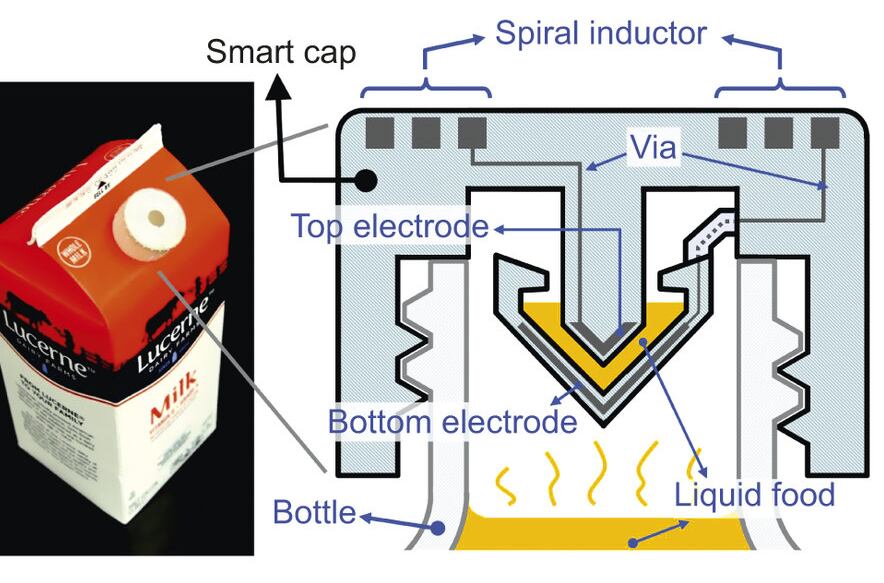

A "wirelessly readable" 3D-printed inductor-capacitor tank (LC tank) was then embedded in a milk carton cap.

With a "quick flip" of the carton, a small amount of milk becomes trapped in the capacitor gap.

Any change in the electrical signals that accompany an increase in bacteria levels can then be measured with a reader.

To test their 3D-printed 'smart cap', a carton of milk was left unopened at room temperature for 36 hours.

“The results showed a 4.3% frequency shift for a milk package stored under the room temperature environment for 36 hours," the study, published in Microsystems and Nanoengineering, concluded.

Speaking with Berkeley News, Liwei Lin, a professor of mechanical engineering at the Berkeley Sensor and Actuator Center, said future development of 3D-printed food safety technology like the 'smart cap' is realistic.

"This 3D-printing technology could eventually make electronic circuits cheap enough to be added to packaging to provide food safety alerts for consumers," he said.

"You could imagine scenario where you can use your cellphone to check the freshness of food while it's still on the store shelves."

Source: Microsystems and Nanoengineering

Title: 3D-printed microelectronics for integrated circuitry and passive wireless sensors

Authors: S-Y Wu, C Yang, W Hsu, L Lin