Since June 2017, the tiny Gulf state has been forced to make some major changes after Saudi Arabia and the UAE, with which it shares land borders, closed access to the country in a row over Qatar’s supposed support of Islamist terrorist groups, which Doha denies.

Since then, a country that was only really an exporter of liquefied natural gas—the biggest, in fact—has been taking an impressive stab at becoming self-sufficient in some other areas.

Perhaps surprisingly for a nation with an average of 75mm of rainfall a year and a distinct lack of farmland beyond small date plantations, it has seen particular success in farming, and in dairy in particular.

Since the boycott, as the blockade is colloquially know, was imposed, Qatari authorities have set out to boost agricultural production by setting up 1,400 farms covering 45,000 acres of land by 2022. Most of these will be given over to the production of less water- and soil-intensive vegetables and fruits, using hydroponic technology for production.

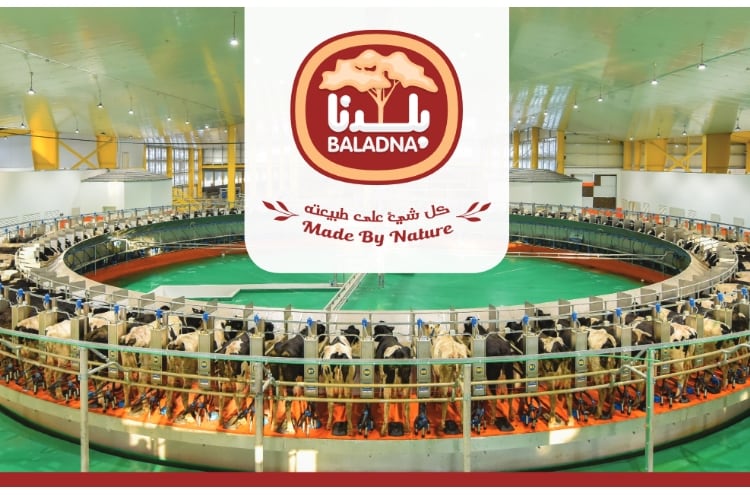

To address the country’s growing need for dairy supplies, 4,000 cows were airlifted into Qatar soon after the blockade, and with these was set up an enormous dairy farm. Later on that year, Qatar opened a US$7.4bn port designed to become a regional transport hub to replace the trade routes cut off by its erstwhile partners in the Gulf.

By December that year, Baladna Food Industries, the fledgling sheep raiser that had been charged with ramping up dairy production just a year after it had been established, was given to claim daily production close to 70 tonnes of full-fat and low-fat milk. It also had a further 10,000 head of cattle ordered for shipment to the new port. The company had begun milking its first cattle within just a month of the closure of the borders.

A few months later Baladna’s chief executive announced it had started working on the construction of 40 new farms with full facilities, as well as the construction of two water treatment plants and feed storage feed storage facilities.

Bigger portfolio

It is not known how much was invested in Baladna and Qatar’s dairy production, but it looks like however much money was spent represents good value.

The initial 4,000-head herd has since expanded fivefold and is well on the way to the 24,000 it had targeted in the wake of Qatar’s isolation. The animals, most of which have been bought from top breeders in the US, live in vast air-conditioned sheds at a farm located in Umm al Hawaya, about 55 kilometers from the capital city, where temperatures can surpass 50 degrees Celsius in summer.

Now producing 320 tonnes of milk each day, according to an official in April, the company has succeeded in making Qatar self-sufficient in dairy, and has even started shipping supplies of fresh milk to Afghanistan, Yemen and Oman, with Libya soon to be added to the list of recipients.

Baladna’s portfolio now comprises of fresh milk, ayran, laban, yogurt, Arabic ghee and cheese. Last year, it also established itself as the provider of 95% of Qatar’s fresh milk demands.

It currently produces twice as much milk as its 2.7m population requires, with the rest sent to the new overseas markets. This is a considerable achievement, given that in 2017, Qatar imported 80% of its dairy.

Taking on juice

Earlier this year, the company commenced the third phase of its expansion—the first two phases had been completed within just 20 months—with the launch of Qatar’s first UHT production line. At an investment of QR21m (US$5.8m), the new line uses European equipment to produce an anticipated 80 tonnes of long-life milk daily.

“Innovation has always been at the heart of what we do in Baladna, and enabling the country’s first UHT milk line is only the beginning of our expansion journey," chairman Moataz Al-Khayyat, who co-owns the company with his businessman brother Ramez Al-Khayyat, said at the launch of the line in February.

“With nearly 20,000 Holstein cows in our barns, we have the capacity to expand our product portfolio, leading to a range of new healthy products in the market.”

Talk now centers on an IPO, which was initially mooted in the early months of the blockade but now appears to be turning into a reality. The much-awaited floatation was confirmed in local newspapers two weeks ago and is expected to hit the stock market in the last quarter of this year. The move has since been given approval from the Ministry of Commerce and Industry, which is required on the rare occasions when a Qatari company is taken public.

With the dairy business running nicely, the company has recently moved into the fresh juice market in a bid to bring self-sufficiency to another segment. Given Baladna’s experience in doing this in dairy, it can only be a matter of time.