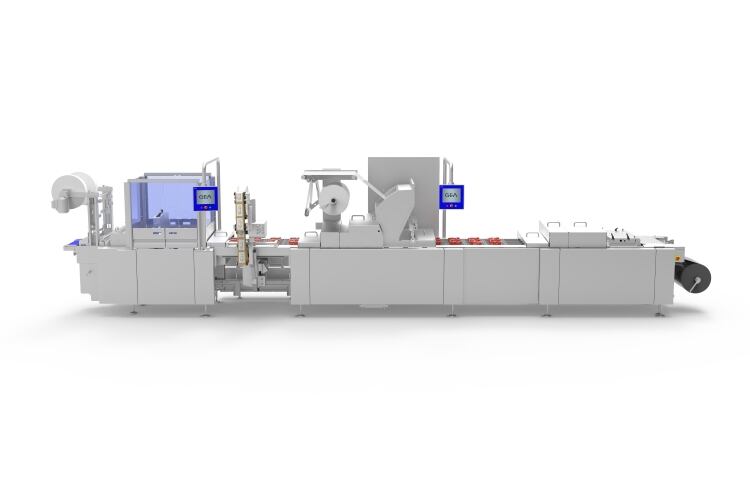

GEA said the slicer is fast and accurate in slicing, with as bigger cross section as existing slicer type GEA MegaSlicer XXL. Therefore, positioning of the new slicer is in between GEA’s Mega and DualSlicer.

According to the company, the OptiSlicer 6000 has a higher capacity, better blade design for a smoother cutting action, eye-level electronics and a new clear-view operator panel.

Regularly shaped products, such as cheese, as well as products known to be difficult to slice, can be handled without the need for crust freezing. The OptiSlicer 6000 can also be mirrored in left and right-hand versions to minimize footprint and enhance productivity.

The OptiSlicer 6000 operates at up to 1,500 rpm. The wide cross section, up to 500mm width x 200mm height is capable of handling multiple product logs, of up to 1,850mm length simultaneously, giving the highest capacity in the sector, GEA said. The company’s new FlexGripper avoids the need for the logs to be manually trimmed, simplifying the machine operation, saving time and potentially reducing product losses.

The new machine uses the same 40° slicing angle as its predecessors, however, the blade on the OptiSlicer 6000 avoids balancing weights to improve hygiene and minimize noise. The wide inner hole allows integration of the counterweight into the rotor. The fixation screws close to the blade edge make it slimmer, more stable, and with a smoother cutting action. It’s also easier to maintain and exchange. The blades have optimized geometry and a new coating, GEA Resyst, for a smoother, more accurate cut and better portion control. The machine also features GEA’s idle-cut rotor that moves the blade, not the product, during idle cuts to improve productivity and minimize product losses.

As there is no need for crust freezing, GEA said this eliminates the need for a freezing unit and the associated CO2 or N2 consumption. This improves productivity, as product preparation time is reduced, and the overall footprint of the line is downsized.

The new high-resolution, full-color operator panel has a 21.5-inch display to provide a high-definition window into the new control system, GEA SmartControl. The new system gives a clear view of the machine status and operation. It offers multi functions with optimal recipe management and access to all relevant documents including the user manual. Operating rights can be allocated to each individual operator as desired and will be protected with personal RFID logins. The system also now offers optional line control, which allows an authorized person to control the whole line from any individual control panel, e.g. recipe change at one panel for the complete line.

The control and electrical systems on the OptiSlicer 6000 comply with all relevant European and USA regulations, even UL (Underwriters Laboratories®)-labelled execution is available. All cabinets (pneumatic and electric) have been placed at eye level for convenient maintenance. Where required, the electrical control cabinet can be located externally.

The OptiSlicer 6000 is available as a standard version (operated from left side) and a mirrored version (operated from right side). This allows the machine to be adapted to production restrictions due to floor space or logistic needs. It also allows the mirroring of two machines to be run by the same operator, improving productivity and reducing the overall footprint of the line.

The design uses common components where possible. For example, the same grippers are used on the OptiSlicer 6000 as on the MegaSlicer XXL and DualSlicer II 1200. Also, the blades are identically to the DualSlicer II 1200. Servo-controllers and other electronic and control parts are common to other GEA systems to simplify maintenance.

The OptiSlicer 6000 is available as 1,200 mm and 1,850 mm versions. The 1,200mm version can be upgraded to the 1,850mm version later, if required.