We chatted with Brad Tripp, sales manager at Green Source Automation, about automation in the age of pandemics; Are Traasdahl, co-founder and CEO of Crisp, about how retailers can predict demand; and John Umhoefer, executive director of the Wisconsin Cheese Makers Association, about how the coronavirus pandemic is affecting cheese production and consumption in the US.

We also have our weekly look at the global dairy markets with Liam Fenton, from INTL FCStone.

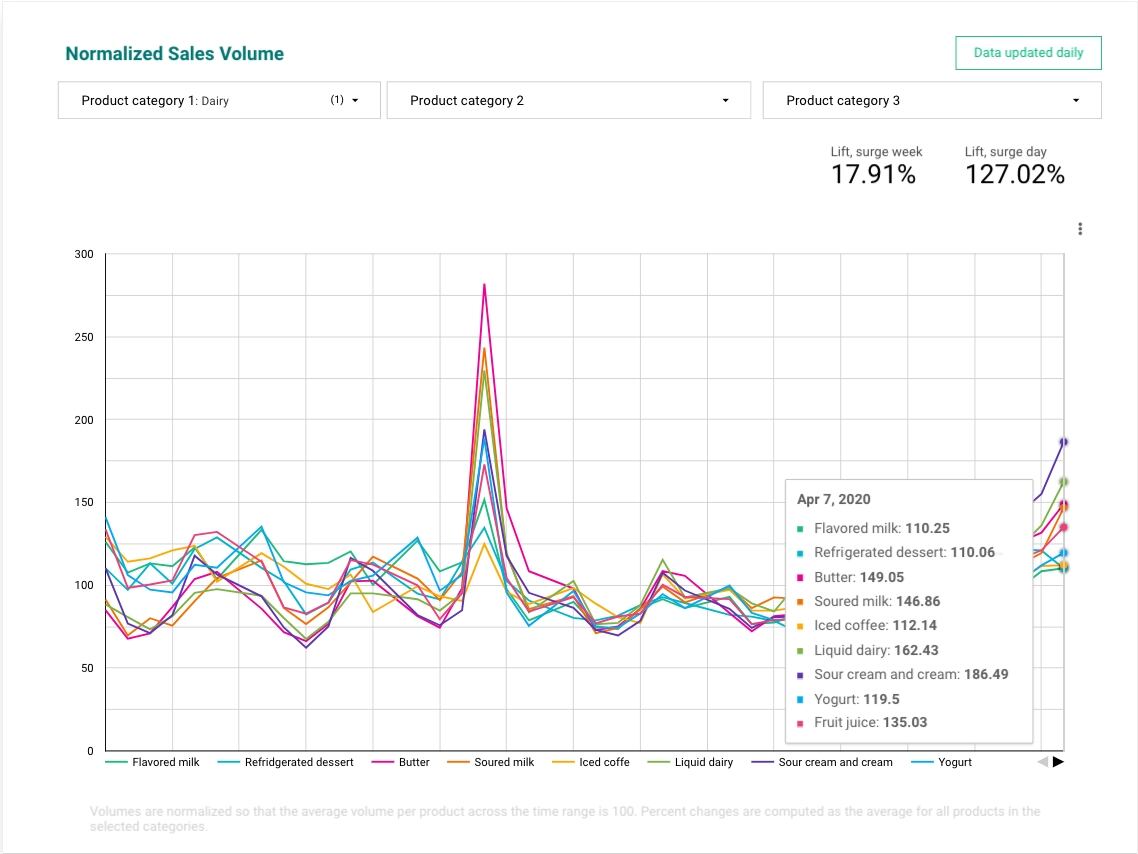

COVID-19 data modeler by Crisp lets US food manufacturers better predict consumer demand

A new data modeling tool is available from Crisp that leverages real-time European consumer food-buying data to help US grocers and food manufacturers better predict American consumer behaviors during the pandemic.

As European countries were impacted by the COVID-19 virus two-to-four weeks ahead of the US, the real-time grocery data from Europe enables US retailers and food suppliers to forecast what consumer demand will be for their particular products.

By using Crisp’s DemandWatch modeler, US grocers and food manufacturers can easily identify categories of food that have experienced greater or lesser demand and proactively modify their supply chain and production capacity to more effectively meet the demand for specific categories of products in the coming weeks, possibly months.

Examples of categories being modeled include dairy, dry goods, fresh food, frozen, beverages and non-food items such as paper goods.

The DemandWatch data model is updated in real-time and is free to grocers, retailers, suppliers, brokers, distributors, CPG manufacturers and other organizations along the supply chain, as well as news media at www.gocrisp.com/demandwatch.

“By working with our European customers, we are modeling customer buying behaviors in real time,” said Are Traasdahl, co-founder and CEO of Crisp.

“Having this data available and knowing that US behavior is following European behavior at a two to four-week time span is critical for US grocers and food manufacturers as they try to predict demand for categories of food and grocery products, restock shelves and meet the needs of citizens.”

AI-driven demand forecasting

Organizations using Crisp’s demand forecasting platform gain immediate insight into consumer food demand down to the store or SKU level based on a variety of market factors. The platform applies advanced machine learning and AI in order to generate forecasts in minutes, bringing together all available data from sales, inventory, third party marketing sources, and promotions.

This helps organizations across the globe create more efficient supply chains and reduce common issues such as food waste, out-of-stocks, and discounted goods, resulting in optimal transactions up and down the supply chain and increased sales, all while reducing global food waste.

Crisp is applicable to specialty and artisan food brands as well as multi-billion-dollar brands. Customers that have realized significant cost savings include Gilbert's Craft Sausages, SunFed Perfect Produce, Nounós Creamery, Hofseth and Superior Farms, among others.

Dairy automation in the age of the pandemic

The world relies on dairy producers as a vital part of the food chain and there is no option to cease production without significant impact globally.

Green Source Automation said its rotary robots provide significant advantages during the current Covid-19 pandemic.

Jim Frias, Green Source Automation president, said, “Robots don’t get sick. Robots don’t expose others to viruses and robots don’t stop doing their jobs. In light of the current pandemic people are seeing robotic automation in a whole new light and the use of robotic technology is growing significantly.”

The current pandemic has not only increased the use of robotic technology around the world, but it has also seen a variety of new uses for existing robots.

Agriculture robots and drones have been converted to disinfectant sprayers and deployed throughout China. Robots are being used to disinfect hospitals, public places, and transportation systems. They are being used in patient care modalities as well as the testing and manufacturing of vaccines and drugs. Robots and drones are being deployed by public safety agencies and they are being used throughout various steps in the supply chain from inventory picking to the loading, transportation and delivery of goods.

Green Source Automation operations manager Casey Taboa added, “Our customers are using robotic automation to address staffing shortages as well as social distancing issues while increasing efficiencies in production and improving economic outcomes.”

With Covid-19 in mind, Green Source Automation’s RotaryMATES eliminate contact points between animals and humans, and their end of arm tools are continually immersed in sanitizing solutions.

There are, of course, still concerns to address. For RotaryMATE teat spray robots and teat prep robots with brushes to continue to operate at the highest levels of efficiency and effectiveness, they must be maintained properly and that often means human interaction.

Green Source Automation said it is taking steps to reduce the possibility that technicians could bring any virus into customers’ rotary dairy parlors.

Green Source Automation’s RotaryMATE dairy robots reach processing times as fast as 4.4 seconds per stall for teat cleaning, teat sanitizing and teat stimulation.

US dairy groups send letter to government

The Wisconsin Dairy Alliance says dairy farmers are dumping milk into fields and down drains, retailers are limiting consumers dairy purchases, and farmers are left questioning if the milk they produce will be get picked up or if they will even get paid.

It adds major segments of the milk marketplace dried up virtually overnight. The shutdown of the nation’s schools, restaurants and coffee shops obliterated major dairy markets, leaving cheesemakers and milk processors with nowhere to ship what they produce.

To address this, groups representing dairy farmers and cooperatives in the Midwest have joined together to urge the federal government to provide direct assistance to farmers and to expedite the purchase of additional dairy foods amid unprecedented disruptions in supply and demand due to the COVID-19 national emergency.

In a letter to the US Department of Agriculture, the groups cited the mass closure of restaurants, schools and other food service outlets, decimated export markets and a sharp drop in prices farmers are being paid for their milk.

“Direct relief to dairy farmers and a substantial purchase of dairy commodities by USDA can ensure our industry will remain fiscally able to function in its primary role of feeding the nation and the world,” the groups said.

The letter was issued jointly by Cooperative Network, Dairy Business Association, Edge Dairy Farmer Cooperative, Professional Dairy Producers of Wisconsin, Wisconsin Cheese Makers Association, Wisconsin Farm Bureau and Wisconsin Farmers Union.

In pushing for product purchases, the groups specifically asked USDA to focus on non-fat dry milk, butter, cheddar, mozzarella, other Italian styles of cheese, and dairy products purposed for use by restaurants and food service vendors.

The recently passed CARES Act directs $14bn to the Commodity Credit Corporation, $9.5bn to a dedicated disaster relief fund for agriculture, $25bn for SNAP programs and $450m to support food banks serving the food insecure.

“This bill enables unprecedented support for farmers and unprecedented commodity purchases, and we need USDA to bring these forms of aid to bear immediately,” the letter said.

“Dairy manufacturers have seen their largest market channel — food service sales to restaurants, schools, colleges, and destinations — deeply cut in the effort to curb the spread of COVID-19. Sales lost at hundreds of thousands of restaurants and institutions cannot be replaced, and our industry looks to the US government to purchase dairy products to move to food pantries and family feeding programs,” the Wisconsin Cheese Makers Association said.

The National Milk Producers Federation (NMPF), the largest organization of US dairy farmers, and the International Dairy Foods Association (IDFA), have also submitted a request for assistance to Agriculture Secretary Sonny Perdue.

Milk Crisis Plan

The overview, called the Milk Crisis Plan, being presented to Congressional Ag Committee Leaders, Secretary Perdue, and leadership at USDA and the White House, outlines how this crisis is affecting US dairy from farm to fork.

The IDFA said the main problem is clear: “We estimate that supply exceeds demand by at least 10% – a gap that could widen as supply increases to its seasonal peak and as “shelter in place” conditions endure.”

Ultimately, the IDFA said, the goal is to ensure the USDA and the Administration use every strategic tool in its arsenal to bring balance to the dairy industry as quickly as possible; and harness the productive capacity of US dairy to address the growing and widening food insecurity facing many Americans and others around the world.

The objectives of the plan are to use as many tools as possible – as quickly as possible – to bridge the supply/demand gap, provide aid to dairy farmers, and alleviate financial/liquidity risks across the supply chain.

The plan also aims to stabilize commodity markets, fill US food banks with dairy products to the growing number of people in economic distress, and immediately address food insecurity by removing restrictions that limit availability of dairy products across USDA food and feeding programs.