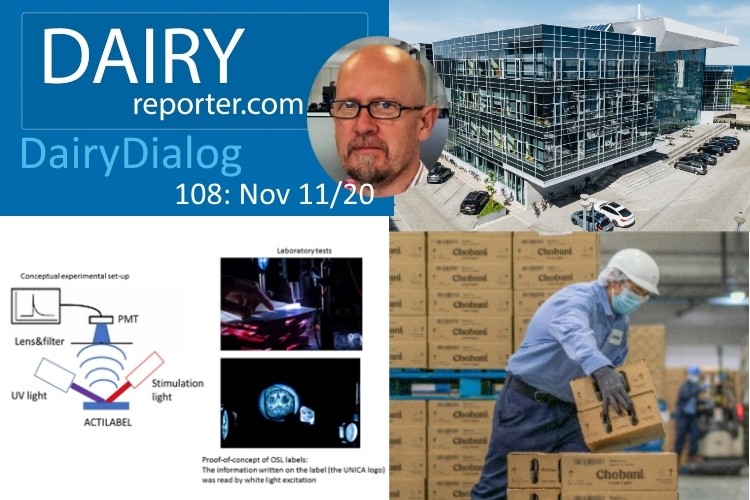

Dairy Dialog podcast 108: Chobani, Novo Holdings, University of Cagliari

Novo Holdings leads €22m investment in The Protein Brewery

Novo Growth, the growth equity arm of Novo Holdings, an investment and asset management company, announced it has led a €22m ($25.9m) Series A investment in The Protein Brewery, an innovative developer of protein-rich, animal-free food ingredients.

Based in the Netherlands, The Protein Brewery was founded in January 2020, resulting from a demerger of BioscienZ, an industrial biotechnology company developing new technologies based on microbial fermentation. It was founded in 2010 by Wim de Laat, a molecular scientist. The Series A funding will enable The Protein Brewery to continue its R&D activities, cover operational costs as well as scaling up production of its flagship product Fermotein.

The Fermotein product requires regulatory approval for application as a food ingredient. The Protein Brewery is already in the application process for the US and European markets, with regulatory approval anticipated in 2021 in the US and 2022 in Europe.

Thomas Grotkjær, principal at Novo Holdings, said, “Integrating alternative proteins that successfully deliver on sustainable development goals is essential to feed a growing world population while taking care of the future of our planet and its people.

“The Protein Brewery meets the criteria investors seek in this space: the state-of-the-art quality, which is superior to all current options in the marketplace. Fermotein has a strong nutrition and sustainability profile and can be applicable to a wide range of high-demand products. With it, the company is well positioned to enter a €30bn-plus market for alternative proteins. This investment underscores Novo Holdings’ commitment to supporting companies that translate biotechnological research and innovation into commercial solutions. We look forward to contributing to the growing commercial success of the company with Wim, his team and our fellow investors.”

de Laat, founder of The Protein Brewery, said, “Providing food for a population of 10bn people by 2050 demands alternative scenarios. It is an important driver in our mission to contribute to a more sustainable world, developing novel ways of producing food proteins. The financial support and domain expertise of our investors will help us take the next important step and move towards the realization of a pilot plant, demonstrating the process, the properties and benefits of our innovative and nutritious food ingredient.

“It is paramount in the development of our company to continue the journey with committed shareholders who share the know-how, drive and enthusiasm for producing natural based food. We are delighted that Novo Holdings, one of the world’s preeminent investors in biotechnology, recognises the potential of our technology to transform the food industry.”

Grotkjær will join the Supervisory Board alongside the other Series A investors, Edouard Nuttin of Roquette Ventures and Kim Odhner of Unovis Asset Management.

New monitoring system could save thousands of tons of wasted food

Thousands of tons of wasted food could be saved every year due to a new monitoring system in development that pinpoints the expiration of perishable produce, even after a ‘use-by’ date has expired.

Blanket ‘use-by’ dates could be a thing of the past thanks to the new accurate monitoring system being developed by Italian scientists at the University of Cagliari that aims to check the past exposure to warmth and genuinely tell whether food is unfit for human consumption.

Around 88m tonnes, equivalent to $169bn of food is wasted every year in the EU alone, based on estimated dates for when food items are no longer safe to eat.

Professor Carlo Carbonaro and his team of researchers at the University of Cagliari have developed low-cost technology to provide precise and reliable indication of whether or not food is still edible.

Carbonaro and his team are working with ACTPHAST 4R – an EU innovation hub designed to give researchers working in academia throughout Europe access to top-level expertise and technologies in photonics to produce demonstrators for their scientific breakthroughs, similar to the supports provided by the separate ACTPHAST 4.0 innovation hub for European companies, especially for SMEs – to further develop their food monitoring device that relies on photonics (the technology of light).

Tracking historic temperatures of perishable food with a handheld scanner and a sticky label that reacts to ultraviolet light, the new technology can monitor past conditions that alter shelf-life.

Creating a historic ‘heat map’ that indicates exposure to warmth, the technology can provide an accurate window of expiration and give food companies a more precise picture of whether a food item has been affected during transit.

Containing a tiny sachet of powder patented by the Italian scientists, the sticky label reacts to the ultraviolet light scanner, indicating the food item’s unique status on a particular day.

Supply chain workers can then assess the likely expiration date against a set of pre-programmed criteria in real-time to optimize the transport of goods - effectively fine-tuning the food item’s use-by date by the time it reaches a supermarket.

Carbonaro said, “Thousands of tons of wasted food can now be saved every year with our highly accurate optical food monitoring label.

“The handheld scanner allows us to extract an average temperature of the food: we exploit UV to activate our labels, and then use visible light to excite the Optically Stimulated Luminescence to read its history - extracting an average temperature which is compared to an expected value.

“Changes in temperatures during transportation can affect the shelf-life of fruit, for example, so we can tell instantly whether the foods have been exposed and how likely this will modify the expiration period. We can add a level of assurance even after a food item has passed its use-by date.”

While the innovation project began approaching the technology from a food waste point of view, it soon became apparent the UV monitoring labels had other beneficial uses.

“Our studies on wine showed that although the expiration period is not necessarily affected by the changes in temperature, the heat can have an impact on flavor, which is a very important criterion for vendors, producers and consumers,” Carbonaro said.

The research team also received business coaching to develop their commercialization strategy for their innovations.

“In parallel with our technical development work, we have also been working with prospective industrial users of the innovation to gain their feedback, so that we can better understand their requirements and validate the application use cases. We hope to license the technology or create a new spin-out company to bring the innovation to market in the next two years.”

As part of the ACTPHAST 4R collaboration, the lead researchers also complete an internship at the relevant photonics competence centre within the ACTPHAST 4R network where they receive hands-on training in working with the cutting-edge photonics technologies that are essential to building their demonstrator.

ACTPHAST 4R operates a continuous open call for researchers who wish to apply for innovation support. Applications can be made online via the ACTPHAST 4R website.

Chobani increases starting wage to minimum $15 per hour

US Greek yogurt maker Chobani has announced the company's starting hourly wage will increase to at least $15 an hour, more than double the federal minimum wage.

The company said the commitment is to put people over profits with robust employee benefits. The changes take effect in the first quarter of 2021.

Chobani's average hourly rate at the company's manufacturing plants in South Edmeston, New York, and Twin Falls, Idaho, will be approximately $19 an hour –above the federal minimum wage of $7.25 an hour. And for Chobani's hourly employees in New York City, including those who work at the Chobani Café in the SoHo neighborhood of Manhattan, the company is raising minimum starting wages to $18 an hour, given the region's high cost of living.

Currently, approximately 70% of Chobani's employees are paid hourly.

"This moment of uncertainty is a call for us to join together to strengthen communities and support those working tirelessly to make the food on the tables of families across America," said Hamdi Ulukaya, founder and CEO of Chobani.

"Businesses should serve the people and communities in which they operate. Raising our base starting salary is the right thing to do and we hope other businesses, particularly food manufacturers, feel the same as we all work toward rebuilding our country."

In addition to full healthcare benefits and a company-sponsored retirement plan, Chobani said it also offers special bonuses and support for frontline workers. Since the onset of the Covid-19 pandemic, Chobani said it has implemented health and safety measures to keep its people and their families safe, including PPE, meals and increased financial benefits.

The company created additional ways to support its employees, including paying special incremental bonuses to all hourly plant employees for the past three quarters, which are continuing, and an ongoing daily childcare subsidy to support those who found themselves without childcare options due to closed schools and childcare centers.

The company also has a rewards program, Chobani Rewards, an initiative that allows every full-time employee to share in the growth of Chobani.

Also, in 2017, Chobani implemented a new paid parental leave policy, offering 100% paid parental leave for six weeks for all full-time hourly and salaried employees. The program extends to all parents for the birth, adoption, or placement of a foster child into the home. In addition, the company covers three rounds of IVF and fertility preservation for all full-time employees, including hourly frontline workers.

Chobani said it is committed to pay equity throughout the company. Each year, Chobani conducts a pay equity analysis to ensure that employees in similar job levels are being paid fairly based on justifiable compensation factors, like their tenure and performance.

Chobani has established and standardized pay ranges for hourly roles, leading to greater transparency around compensation and setting clear expectations with employees for their growth over time within the organization.