We also have our weekly look at the global dairy markets with Liam Fenton at StoneX.

Chr. Hansen launches next-generation Premium cultures for fresh dairy producers

Chr. Hansen is launching its next-generation Premium cultures, which help producers achieve their strategic goals, whether they wish to offer indulgent, high-texture yogurt with fewer additives; improve margins by reducing the need for expensive skim milk powder; or create healthier, premium yogurts with the optimal amount of probiotics.

YoFlex Premium: Fewer additives for a cleaner label and more affordable products

YoFlex Premium uses the power of good bacteria to create high texture naturally, reducing the need for expensive added ingredients, such as skim milk powder. With YoFlex Premium, producers can make the change they need, whether it is differentiating their offerings within the premium segment with an all-natural ingredients list or reducing costs by reducing inputs.

“YoFlex Premium is unique because it yields exceptionally high mouth thickness and mild flavor, both of which are crucial for creating new taste experiences,” said Thomas Skaaning, senior vice president, Food Cultures & Enzymes, Chr. Hansen.

“While taste is the primary differentiator for many dairies, the most strategic players in our industry succeed because they understand that texture is the other half of the equation, as it strongly influences how taste is perceived.”

Skaaning added, “Earlier this year, results from a survey we conducted in France found that texture scored second-highest among purchase motivators for consumers buying yogurt and fermented milks, after value for money. To us, this underscores the additional value of YoFlex Premium, because it suggests that consumers will welcome the enhanced texture it creates, irrespective of whether producers are looking to reduce added ingredients or lower costs.”

nu-trish Premium: A response to consumer interest in foods that support health

Chr. Hansen is also launching three new nu-trish Premium cultures that include the world’s most-documented probiotics linked to immune and digestive health, Bifidobacterium, BB-12 and Lactobacillus rhamnosus, LGG.

With recent events, consumer priorities have evolved worldwide, with six out of 10 stating they are more conscious of their immune health and general well-being than before. The company cited an FMCG Gurus report that stated 35% of global consumers have reported an increased use of foods to boost immunity, and 70% of consumers in Europe and 77% in the US associate probiotics with helping to boost immune health.

“Never before has the need to eat for health been more urgent. In this way, our launch of nu-trish Premium’s newest generation comes at the perfect moment, enabling producers to offer premium yogurts while helping to support the health of consumers. And as we look to the future, we are committed to helping shape a food system that can not only feed the world, but help it thrive, too,” Skaaning said.

“Together, this newest generation of Premium cultures represents an opportunity for fresh dairy producers to elevate the value of traditional yogurt by advancing its inherently tasty and nutritious benefits in a natural way. This makes the Premium cultures The Perfect Partner for producers committed to excellence,” Skaaning added.

This newest generation of Premium cultures mark the beginning of a new chapter in Chr. Hansen’s ongoing collaboration with dairy producers to ensure their products remain relevant amid a shifting competitive landscape.

“We look forward to illustrating for our customers why these next-generation Premium cultures are The Perfect Partner for the raw material milk —but we also hope that producers continue to see Chr. Hansen as the ‘perfect partner’ in a more holistic sense,” Skaaning noted.

“With this launch, we underscore our commitment to working alongside our customers, co-creating food products whose taste, texture, and health benefits delight consumers and support their well-being. Together, we can raise the bar and advance the frontier for what is possible for yogurt-making.”

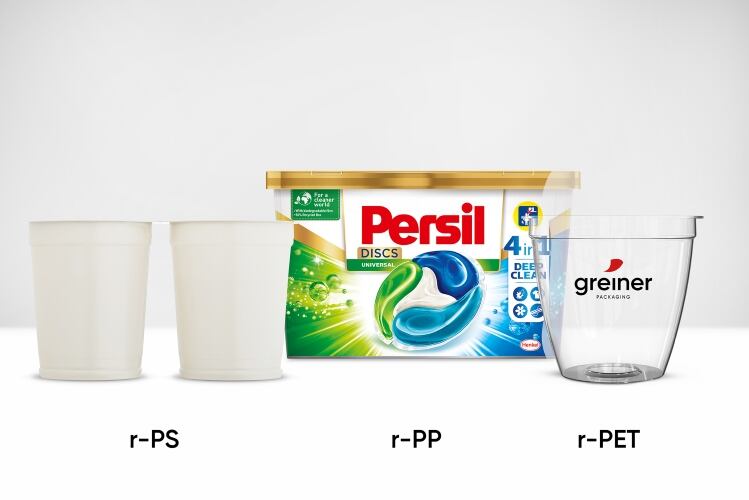

Greiner Packaging extends range of recycled materials

While polypropylene (PP) and polystyrene (PS) are the most commonly used materials in the dairy packaging industry, some of the recyclates from both materials still lack approval for use in food packaging and have only limited availability.

However, r-PET (recycled polyethylene) is readily available through existing bottle recycling streams, but has so far been largely unsuitable for dairy packaging due to its material properties.

Where high temperature sterilization (HTS) is required, PET has to withstand temperatures of up to 120°C. With initial tests for the use of r-PET HTS in packaging for dairy products, Greiner Packaging is expanding its material competence and adding another component.

At the moment, r-PET is the only food-approved recycled material, while r-PS and r-PP are still in the test and approval phase. It is therefore important to provide dairies with a recycled material that can withstand the necessary production processes.

Greiner Packaging said crystalline-PET (CPET) does not represent a solution for the dairy market. While it can withstand hot sterilization of up to 240°C, the nucleating agents contained in it make recycling difficult.

A distinction is generally made between mechanical and chemical recycling of r-materials. The former has a better carbon footprint, while the latter enables dirty yet valuable material or composite material to be recyclable. Although the chemical process is a little more complicated, the quality of the product is comparable to virgin material, which means approval for its use in food packaging is assured.

Mechanically recycled PET is available in relatively large quantities from the material cycle, which means new plastic products can be manufactured from up to 100% mechanically recycled PET for use in the food industry.

Tests are currently under way for the dairy industry to see how PET can tolerate temperatures of up to 120oC during HTS. The main focus will be on how the current sterilization process can be compatible with hydrogen peroxide. The aim is to ensure dairies are not forced to make changes to the filling process when using material such as r-PET.

Greiner Packaging said it is working with its dairy customers on this process.

“We are also in the process of finding an alternative to the PET bottle stream. Obtaining recycled material from different sources would mean us no longer being solely dependent on bottle flakes in the medium and long term. We are currently evaluating different sources and opportunities, as well as having discussions with a number of suppliers who can offer social PET. One example is our work with Plastic Bank,” Jörg Sabo, global marketing and innovation director at Greiner Packaging, said.

Mechanically recycled PP can currently only be used for non-food packaging, however a food approval is in preparation. Chemically recycled PP is suitable for food contact, but not readily available as there are no large-scale recycling streams for PP. Greiner Packaging is currently involved in a project that aims to obtain food approval for r-PP from mechanical recycling.

Recycled PS is in short supply as a chemically and mechanically recycled material. Here too, recycling streams must first be established. However, earlier tests have already shown the high purity content of PS makes it ideally suited to mechanical recycling.

Initial tests in Switzerland have shown Greiner Packaging is capable of producing yogurt containers made from 100% r-PS material. For the first time, 100% mechanically recycled PS was used with 100% recycled cardboard in a joint project with M-Industry.

The process was tested for Swiss K3 twin yogurt packs. Greiner Packaging said the results were promising. None of those involved in the test noticed any sensory deviation as a result of the new, first-time use of r-PS material. The process for obtaining certification of r-PS for use in yogurt containers is already under way in Switzerland.

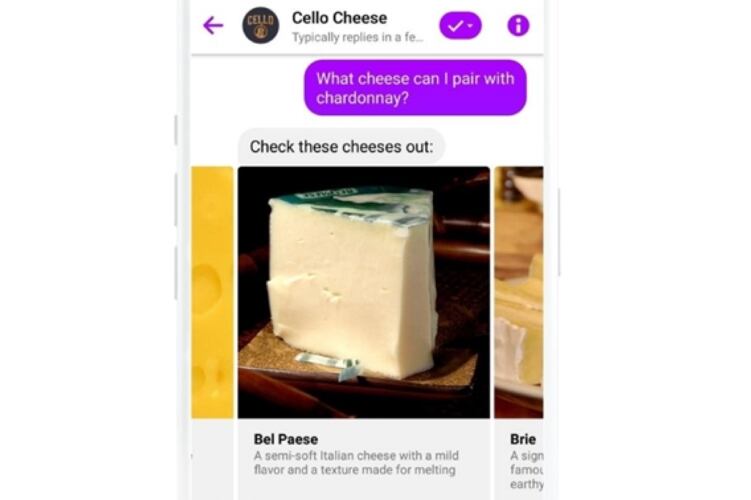

Cello turns to AI for consumer cheese info

US company Schuman Cheese has developed a social media chatbot for its Cello brand as it looks to help consumers learn more about cheese.

The company has also partnered with agency Partners + Napier on a campaign to tackle what it said are the biggest “intimidation factors” in selecting specialty cheese, including how to choose the right cheese and how to build the best cheese board.

“There are a lot of people who love specialty cheese but don’t consider themselves experts, and crave guidance from brands so they can better navigate the category,” said Mike Currie, director of marketing at Schuman Cheese.

“We want people to know that they don’t have to be a cheese connoisseur in order to enjoy premium cheese confidently. All they have to do is look for our distinctive black label.”

The “Cheese Confidently” campaign launched in September and will continue to run in the NYC metro market and along the East Coast at key retailers. The campaign includes online video, social media, digital couponing and DFSIs, SEM, point-of-sale, and a partnership with Instacart as a Featured Product.

Cello Chatbot, which recently launched on Facebook Messenger, gives users immediate answers to product questions, recommendations based on preferences, recipe ideas, and food and drink pairings. The Chatbot will also include a feature that directs user to their local retailer for purchase.

The company not only produces cheese in Wisconsin, but also imports a variety of cheeses from Europe and South America.