In its report, ‘Breathable Films Market by Type, (Polyethylene, Polyurethane, Polypropylene), Application and Region - Global Forecast to 2021’, it says food packaging will provide ‘immense opportunities’ because of the increasing trend of packaged produce and cheese consumption.

Arkema, Daika Kogyo, Skymark Packaging, Innovia Films

Breathable films are thin films made with a combination of polymers and mineral fillers that have a microporous structure for vapor transmission.

The polymers mainly used in breathable films include polyethylene, polypropylene, polyurethane, and those that contain polyether block amide, thermoplastic polyester elastomers, co-polyester, and co-polyamide.

Chiranjeeb Kuila, senior research analyst and author of the report, told DairyReporter the food packaging application is now at a nascent stage and has high potential for growth.

Only 2.5% of the breathable films market size was used in food packaging in 2015. The application of packaging for the food and beverages industry has increased over the years.

He said there is a greater need for flexible packaging, high water barrier materials, and packaging films for high fat content.

In food packaging, vegetables, fruits and cheese need aeration to stay fresh ensuring a reduction in food waste, longer shelf-life, and convenience of use.

The top 10 breathable film manufacturers in the report are Clopay Plastic Products Company (US), RKW Group (Germany), Mitsui Chemicals Incorporation (Japan), Toray Industries (Japan), Covestro (Germany), Nitto Denko Corporation (Japan), Fatra (Czech Republic), Arkema (France), Celanese Corporation (US), and Trioplast Industrier (Sweden).

The key players in the breathable films market for food packaging applications include - Arkema, Daika Kogyo, Skymark Packaging products and Innovia Films.

“A lot of R&D is being carried out on renewable materials such as hydrogel films using synthetic polyvinylpyrrolidone and biopolymers carboxymethyl cellulose,” said Kuila.

“As these films are biodegradable and suitable for food packaging, they can solve the problem of disposal of plastic waste faced by the global packaging industry. Research is being conducted on chitosan, alginates, hemicellulose, nanocellulose, and proteins including whey protein and wheat gluten for food packaging.

“Research on thermoplastic cross linked starch as porogen is also being conducted for producing breathable films.”

North America and Europe

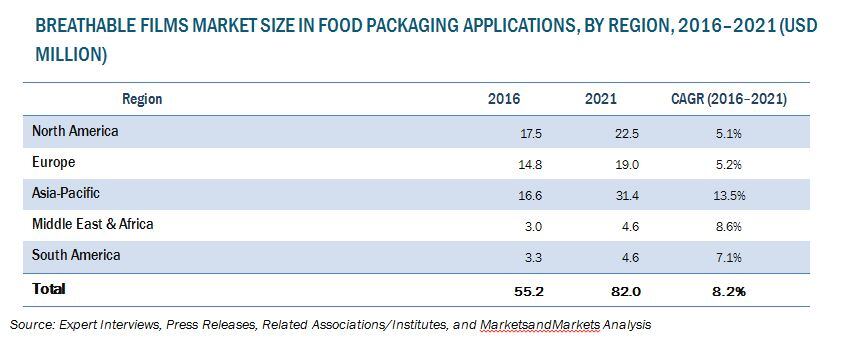

He added, traditionally developed regions such as North America and Europe are the major markets for packaged food items, therefore the breathable films market is leading in these regions with a combined share of close to 60%, in terms of volume, in 2015.

However, due to the shifting trend of consuming packaged food items from the developed regions to developing markets due to convenience, hygiene, and competitive price of packaged food items is expected to drive the market in Asia-Pacific, the Middle East & Africa, and South America.

Breathable films were first introduced in Japan in the 1980s to be used in hygiene applications, particularly as a backsheet for diapers. They were largely accepted in the Japanese market despite the higher costs compared to non-breathable films.

Breathability is measured in terms of MVTR (moisture vapor transmission rate), which measures the transmission of vapors through a material in a given time. It is an important aspect in many industries where moisture can cause damage.

Increasing per capita income and evolution of modern trade further helped the market growth.

In developing countries, the growing adoption of western diets (including packaged cheese and vegetables) is expected to drive the breathable films demand in food packaging.

The main issue with soft unripened cheese is it has a shelf-life of two to four weeks. So, increase in the consumption of packaged cheese with longer shelf-life is fueling demand for packaging with breathable films.

With the increase in commercialization of MAP (modified atmosphere packaging), the demand for use of breathable films in various horticulture products is also rising.

“China is one of the largest countries in the world producing huge agricultural produce consisting of fruits and vegetables,” said Kuila.

“The government is paying more attention to the safety and nutrition of fruits and vegetables. Growth in the supermarkets and growing consumer demand for quality and convenience are the factors that support the breathable films market in China’s food packaging industry.

“There is also increasing demand for fresh produce with improved characteristics in terms of freshness, taste, and flavor. China aims to integrate about 70% of its population, about 900 million people, into cities by 2025. This is a tremendous boost for the food processing industry and in turn for the food packaging industry.

“Due to the current fast-paced society, consumers prefer convenience over cost. There is also increasing need for transportation of fruits and vegetables between northern and southern China for the nationwide distribution of these items. The transportation requires a long time so maintaining the freshness of these products can be achieved by the breathable films packaging.”

‘Nascent Stage’

In India, Kuila added, normal polyethylene films are a predominant material used for food packaging due to their low cost but use of breathable films in the country is at a ‘nascent stage’.

“With such a large number of middle-income families in India growing at a rapid pace and the government’s plan to come up with 100 smart cities in the next decade or so; packaged food consumption is expected to rise,” he said.

Top 10 global breathable film companies

Clopay Plastic Products Company (US)

RKW Group (Germany)

Mitsui Chemicals Incorporation (Japan)

Toray Industries (Japan)

Covestro (Germany)

Nitto Denko Corporation (Japan)

Fatra (Czech Republic)

Arkema (France)

Celanese Corporation (US)

Trioplast Industrier (Sweden)

“Increase in the export of fresh fruits and vegetables to other countries from India will also require packaging items which can provide better shelf-life and freshness for a longer time.

“In Turkey, the food packaging application is driven by the increasing urban population in the country. Around 75% of the total population in the country lives in urban areas and over 60% of the total population is of age 35 and below.

“The urban lifestyle and subsequently less time for cooking due to a rise in the number of women in the workplace will further fuel the growth of the food packaging industry. Considering all these factors, the food packaging application segment for breathable films is expected to rise faster.”

The integration of food packaging applications is also expected to increase in manufacturer’s factories. According to the report, breathable films were initially produced on cast lines and calcium carbonate particles are embedded in it. However, there is a shift of trend in manufacturing through blown film technology as it provides enhanced properties and less thickness. So, through blown film technology there is a scope for material and cost saving.

Breathable films are produced on cast film lines The value-chain of breathable films involves value addition from the raw material suppliers, breathable films manufacturers, and the end-use industries.

Raw materials such as LDPE, LLDPE, PP, and CaCO3 are bought by the breathable films manufacturers. The manufacturers process them and produce breathable films that are supplied to companies producing baby diapers, adult diapers, and sanitary napkins.

Breathable films are also supplied to building and construction companies, medical clothing manufacturing companies, and food packaging material manufacturers.

Key suppliers of HDPE, LDPE, and LLDPE for breathable films manufacturing are: The Dow Chemical Company; Borealis; and LyondellBasel.

Several research studies are being conducted related to various materials which can be used for food packaging.

The object of the study by MarketsandMarkets is to define, describe, and forecast the global breathable films market, based on its type, application, and region; to forecast the market size, in terms of value, of the market segments with respect to five main regions, North America, Europe, Asia-Pacific, the Middle East & Africa, and South America.

It looks at information regarding the key factors influencing the growth of the market (drivers, restraints, opportunities, and industry-specific challenges) and to analyze micromarkets with respect to individual growth trends, future prospects, and contribution to the total market.